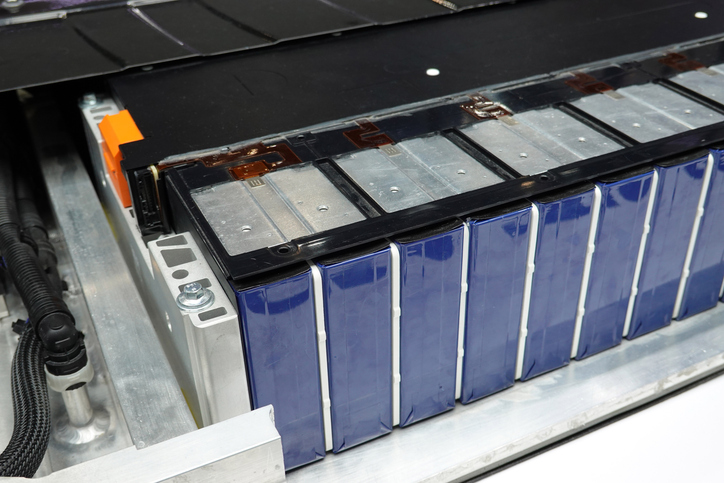

Shrink and release tape, or film has proven to be an essential facilitator in the processing of high-voltage coils and composites. These particular shrink tapes are able to serve dual purposes in the manufacturing of composites, or high-voltage components like coils. With options in the choice of materials and properties imbued into the tape, these materials can be custom designed to enhance specific application uses.

Before we get into the many options available from an expert-level provider of insulation products, let’s examine the important functions of shrink and release tape.

Dual Purposes for Specific Requests

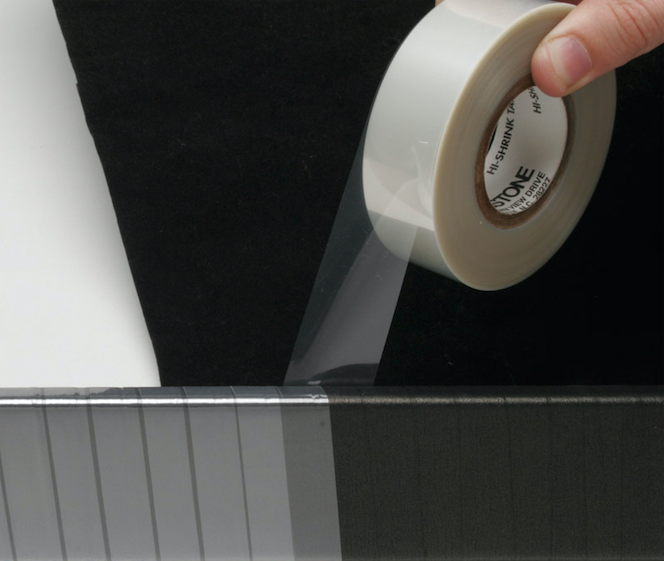

The primary purpose for any industrial shrink tape, including those dealing with high-voltage coils and electrical composites, is to optimize compaction forces during the curing cycle. When working with composites, a resin must be applied between the material layers to create the necessary bond and compress them. The tape, or film, is wrapped around a composite element or high-voltage coil and placed in an oven where it begins to shrink.

As the tape shrinks, the pressure that is exerted in the process forces resin through the composite matrix and between the layers of the material. This brings the layers together as much as possible and reduces voids in the finished part.

Shrink and release tape performs this task, but differentiates itself in its ability to also provide clean ‘release’ characteristics. After the curing process, shrink and release tape can then be cleanly stripped away — which helps provide a smooth finish to the part and aids in cutting down the bulk and/or size of the finished product.

These additional benefits come with none of the drawbacks of limited customization. Providers of insulation solutions, like Electrolock, will offer multiple product lines to further target specific uses or circumstances. Shrink and release tape can come with a release coating on one or both sides of the product, and can be perforated or non-perforated.

And the shrink tape itself is available in many different core materials that further provide specialization. These materials include (but are not limited to):

- PET (Polyethylene terephthalate)

- FEP (Fluorinated ethylene propylene)

- PI (Polyimide)

- ETFE (Ethylene tetrafluoroethylene)

- OPP (Oriented polypropylene)

With the number of variables involved — the type of film used, the thickness needed, the ideal shrink percentage to apply the right force, and the material selected — it is essential to remember that to get the best results out of this process you’ll need to consult with a qualified engineering team. Expert advice will help you select the correct shrink and release tape, and other specifics, needed for your application.

Want to know more about Electrolock? Read about their engineered solutions here.

5 Shrink and Release Tape Solutions

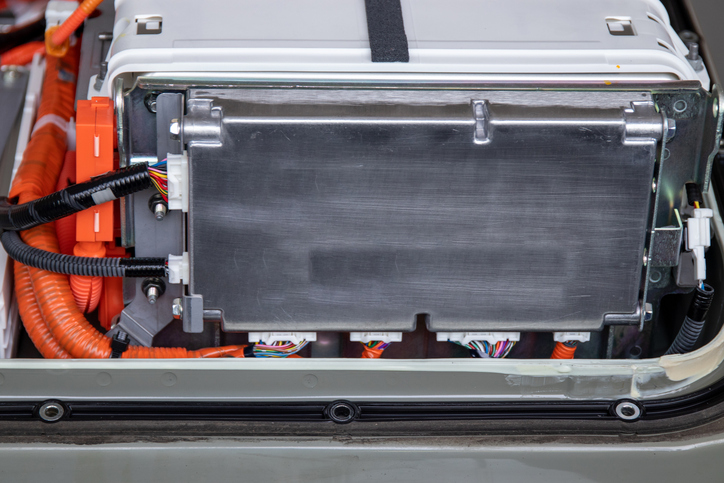

Electrolock is a premier provider of insulation products for high-voltage electrical, battery, and thermal insulation industries. With more than 60 years of experience, we’ve consistently created bespoke solutions to cover all of our customers’ most demanding requests.

In the area of shrink and release tape, our PolyShrink Tape and Freebond Release Film will give you the flexibility and versatility to tackle any compaction processing issue involving high-voltage coils or composites. Our PolyShrink tape comes with our proprietary ‘non-silicone’ release coating on one or both sides to ensure an easy release from the cured part. Freebond film is uniquely made to bond to itself during a cure cycle while still being capable of acting as a release film on the part.

Here’s a closer look at more options for both PolyShrink and Freebond, including technical specifications.

PolyShrink Tape — Our baseline product offering in this realm, PolyShrink Tape comes in variable shrink percentages (210, 212, 218, and 220 corresponding to 10, 12, 18, and 20 percent) with usage temperatures between 200 and 400 degrees F. This tape will have the best overall compacting force, and comes slit to your desired width and wound on 1.5 or 3-inch interior diameter cores with a minimal amount of thickness (0.002 inches).

PolyShrink R Tape — Available in 210 and 220 varieties (10 and 20 percent shrink), this tape features a PTFE coating on one side to provide enhanced release characteristics. Optimum shrink is achieved at temperatures between 80 and 165 C. The cleaner releasing tape comes in similarly sized thickness (0.05 mm) and is wound on similarly sized cores (38 mm to 76 mm).

PolyShrink T — Coming in two shrink percentages (206T and 210T) and one non-shrink (200T) version for use when preventing deforming during curing is absolutely necessary, this ‘tape’ is often is used as one homogeneous film for excellent release characteristics. Optimum shrink is obtained between 120º and 170ºC, and the film is available slit to desired width the usual thickness (0.002 inches) and core (1.5 or 3 inches) sizes.

PolyShrink HT — With a nylon core and a fluoropolymer release on both sides, this film can easily conform to unusual or complex cross-sections, and has the best releasing tape Electrolock provides. While it doesn’t have the strongest shrink force, it does come in minimum (200HT) and moderate (212HT) varieties. The superior release properties will work in processing temperatures as high as 180 C. Wound on 38 mm or 76 mm cores, this tape comes in 0.05 mm thickness and is provided slit to your desired width.

Freebond Release Film — A tough, flexible composite film with multifunctional properties, this product has nominal shrink percentages (2 to 4 percent) with a finished thickness of 0.002 inches and practical use up to 300 F. Freebond provides excellent release characteristics from most cured epoxy resin systems and retains higher tear and tensile properties than conventional release films. A three-ply material with a poly core, Freebond will bond to itself and provide a solid structure or tube which aids in removal after the finished part has cooled. It is NOT coated with silicone or fluoropolymer, thus avoiding the risks associated with products using such coatings.

Ensure your insulation solutions: Learn more about our experienced, expert-level team here.

Proven Solution Providers

Collaborating with businesses since 1957 to engineer unique and tailored solutions for the thermal insulation, battery, and high-voltage electric industries, Electrolock has amassed the experience and expertise to handle any request.

Electrolock will design, fabricate, and then fully test potential solutions, including identifying the perfect shrink and release tape needed for your application. By validating — through an extensive in-house testing system — before entering production, Electrolock is able to save both time and expense on the back-end of a project. No matter what your material or insulation challenge, Electrolock will help you solve it.

Contact us today to schedule a one-on-one consultation or evaluation on your material needs or application specifics.