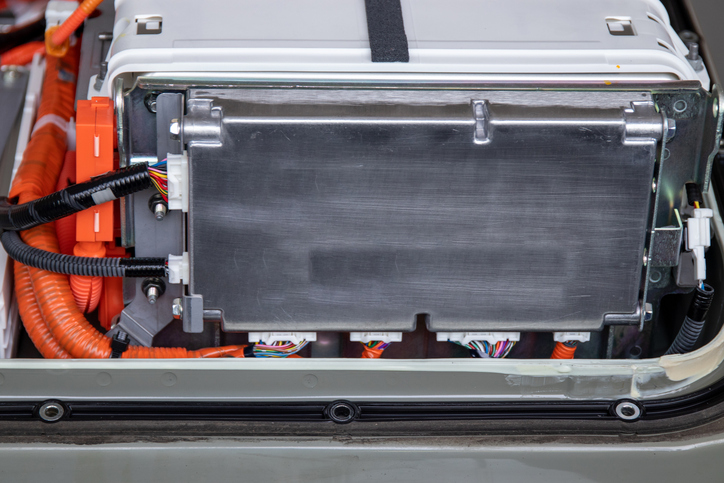

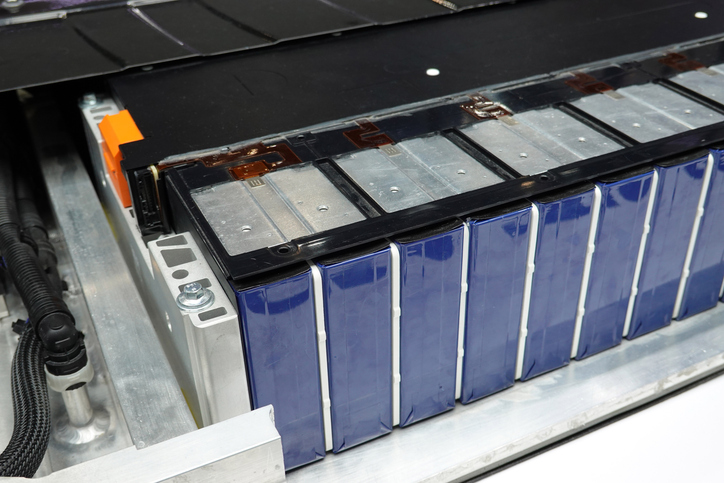

Lithium-ion batteries are powerful and ideal for use in a wide range of applications, particularly electric vehicles. However, lithium-ion systems can become overheated easily and may be prone to damage in extreme temperatures. To combat this, it is important to have the proper thermal propagation barriers within your lithium-ion batteries.

Why are Thermal Propagation Barriers Important?

These barriers (and the materials used to create them) are essential in limiting the impact should thermal runaway occur. They help prevent damage to the battery itself and provide cell-to-cell and cell-to-vehicle protection.

Impeding Thermal Runaway

Lithium-ion systems and batteries can be susceptible to thermal runaway. Thermal runaway is when a battery’s temperature increases rapidly and uncontrollably. The process can ignite fires and even cause explosions, damaging the battery and vehicle while putting the safety of the user at risk. To combat thermal runaway, insulation solutions are used, preventing overheating and the spreading of that heat from one cell to another, ultimately reducing or limiting damage.

Preventing Damage from Temperature Changes

These systems also have an optimal operating temperature. While they can function in temperatures outside of this range, it may cause damage to the battery. When functioning in extremely cold or extremely hot temperatures, the battery may get too hot or have to work too hard for the system to function properly. This can cause the battery to overheat, potentially leading to thermal runaway, or it may simply damage the battery. Luckily, with the proper thermal propagation barriers in place, your battery will be less susceptible to changes in temperature that may damage it.

Electrolock’s Thermal Propagation Barriers

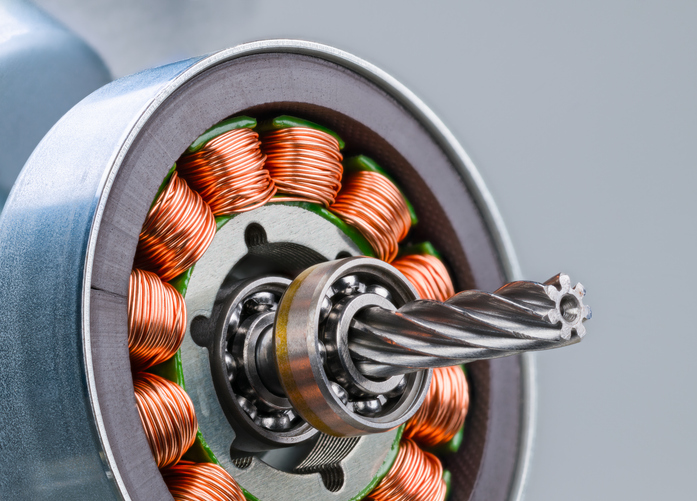

Electrolock offers various thermal management solutions that can improve the safety and efficiency of your lithium battery systems.

Mica Insulation Solutions

Mica offers exceptional electrical insulation and thermal stability. With it being able to resist high temperatures and being flame resistant, this material is a great solution for thermal management in lithium-ion battery systems. It also offers excellent resistance to electrical tracking, high dielectric strength, and dimensional stability.

PET

PET offers good electrical insulation properties and mechanical strength. It is also a lightweight, flexible material that can adapt well to various cell formats and manufacturing processes. PET also exhibits good chemical resistance and is stable across a broad range of temperatures. This is also one of the more cost-effective insulation materials.

Ceramic

Ceramic insulation solutions excel in extreme temperatures, as they will not break down. Ceramic materials are suitable for high-stress applications and applications that require superior thermal management. These solutions are ideal for use where preventing thermal runaway is paramount.

How to Know Which of the Above is Right for Your Applications?

In order to choose the optimal thermal propagation barrier materials, you will need to evaluate several factors. First, you will need to determine the properties of your operating environment, including maximum and minimum temperature requirements, whether there will be exposure to chemicals, and mechanical stress levels. Then you will need to evaluate the performance requirements. This includes the dielectric strength needs, thermal conductivity targets, required service life, and safety standard compliance. Finally, you need to consider manufacturing, including how to integrate with your existing processes, material handling requirements, production volume implications, and total cost of ownership.

When You Need Thermal Propagation Barriers, Turn to Electrolock

Since 1957, our team has been engineering battery insulation systems for batteries, medium and high-voltage applications, and more. We take into consideration the exact parameters of your project and application to match you with the right material, or create the right material for you. We also maintain comprehensive testing capabilities to validate your material’s performance under specific operating conditions.

Contact our team today to learn more, or visit us at the 2025 Battery Show – Europe in Stuttgart, Germany from June 3-5. We will be at booth 8-D71.