Polyester heat shrink materials, be it in applied tape, film, or spiral wound tubing, are critical in the manufacturing and processing of high-voltage components — and composites used across many other industries. Polyester heat shrink tape, in particular, is regarded as one of the best ways to compress composite materials, wet layups, and prepregs that adhere to performance standards long after the curing process.

When utilized properly, our Polyshrink and Freebond shrink products deliver assistance to production teams working with high voltage coils and electrical composites in reaching several goals through implementing one solution:

- Removal of voids in the resin, or between layers

- Elimination of foreign object debris (FOD)

- Improved lamination of the composite material

- Superior surface finish

- Better mechanical strength from the cured part

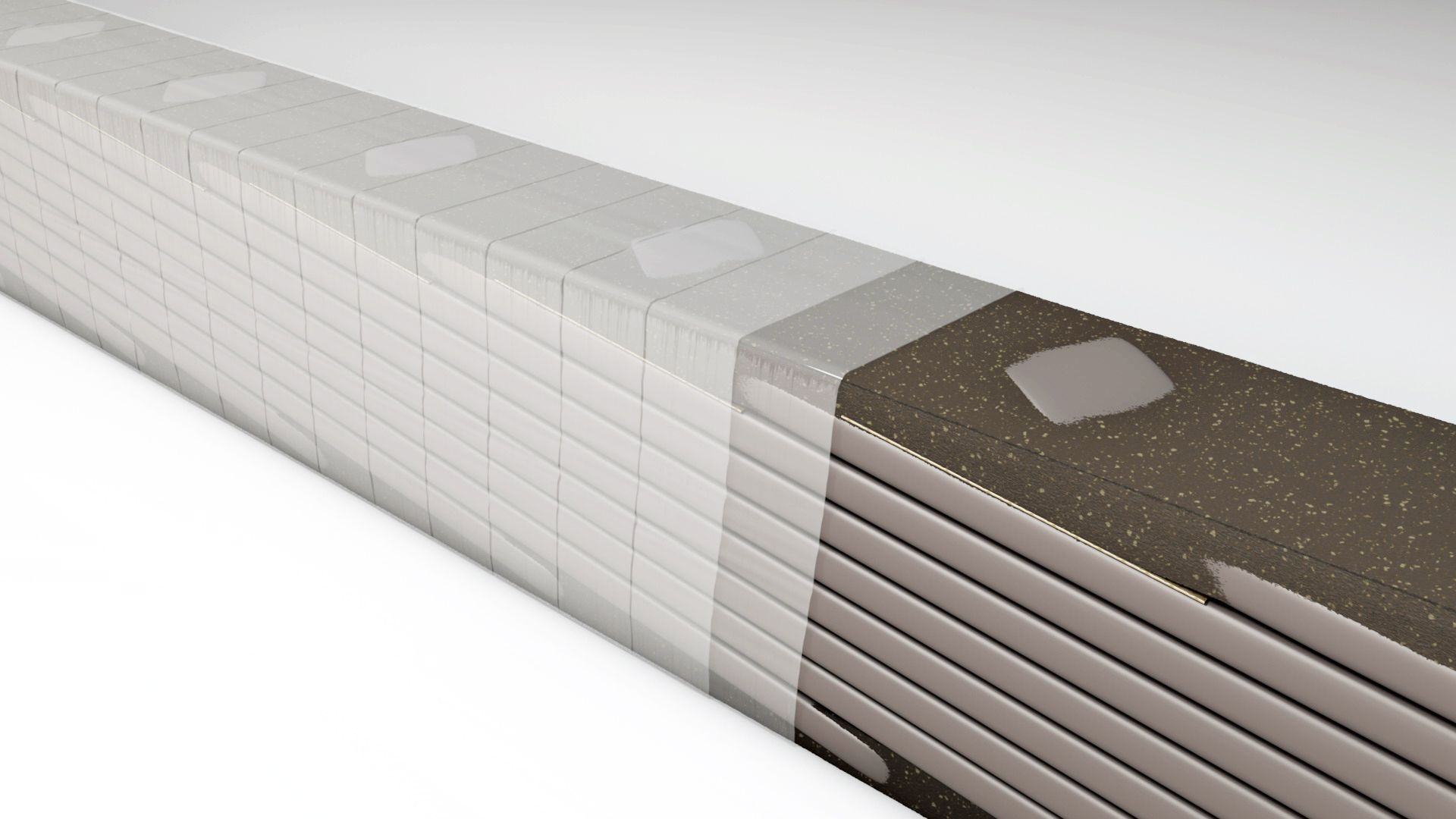

These polyester heat shrink tapes and films can be custom designed to enhance specific application uses, but all deliver on their primary purpose — optimize compaction force during the curing cycle. When working with composites, or high voltage components like resin-rich coils, a resin must be applied between the material layers to create the necessary bond. Polyester heat shrink film or tape is wrapped around the composite or high-voltage coil; Compression occurs during the curing when that tape shrinks and compacts under heat.

As the tape shrinks, the pressure that is exerted in the process forces resin through the composite matrix and between the layers of the material. This brings the layers together as much as possible and reduces voids in the finished part.

This primary function can be further augmented with customization options. Electrolock, for instance, offers multiple product lines to target specific uses, offer greater shrink percentages and compaction strength, perforated or non-perforated tapes depending on the need for outgassing, or release coatings on one or both sides of the polyester heat shrink material.

To get the best results from any heat shrink taping or filming process, it’s critical to consult with an experienced engineering team. Expertise is needed to select the correct type of tape, the thickness needed, and what shrink percentage will deliver the proper amount of compaction force during curing. Film or tape that shrinks too much, or not enough, for example, will have a negative impact on the final product, leading to material waste and extra cost.

We Provide Solutions: Electrolock is your source for Isovolta mica tape productions, widely used in medium and high voltage coil construction and insulation.

3 Examples of Polyester Heat Shrink Tapes and Films

Electrolock’s line of PolyShrink Tape and Freebond Release Film products offers the flexibility and adaptability to conquer any compaction processing challenge involving high-voltage coils or composites. Our PolyShrink tape comes with our proprietary ‘non-silicone’ release coating on one or both sides to ensure an easy release from the cured part. Freebond film is uniquely made to bond to itself during a cure cycle while still being capable of acting as a release film on the part.

Here’s a closer look at more options for both PolyShrink and Freebond, including some technical specifications.

PolyShrink Tape — Our baseline polyester heat shrink product, PolyShrink Tape comes in variable shrink percentages (210, 212, 218, and 220 corresponding to 10, 12, 18, and 20 percent) with usage temperatures between 200-400°F. When compacting force is your primary concern, this tape delivers with a wide range of shrink percentages able to closely match what is needed. It is slit to your desired width and wound on 1.5 or 3-inch interior diameter cores with a minimal amount of thickness (0.002 inches or 2 mils).

Freebond Release Film — A tough, flexible composite film with multifunctional properties, this product has nominal shrink percentages (2 to 4 percent) with a finished thickness of 2 mils (0.002 inches) and practical use up to 300° F. Freebond provides excellent release characteristics from most cured epoxy resin systems and retains higher tear and tensile properties than conventional release films. A three-ply material with a poly core, Freebond will bond to itself that aids in removal after the finished part has cooled. It is NOT coated with silicone or fluoropolymer, thus avoiding the risks associated with products using such coatings.

PolyShrink RR Tape — This is another durable, flexible, shrinkable polyester tape with PTFE coating on both sides to provide enhanced characteristics. Optimum shrink is achieved at temperatures between 80-180°C, making it suitable for applying sufficient compression during heating or curing. PolyShrink RR is generally removed after application. The tape is wound on 1.5 or 3-inch cores and is provided slit to your desired width.

Tailored Solutions for Stator Coils and More: Electrolock offers an extensive list of solutions for applications relating to VPI stator coils and bars and resin-rich stator coils.

Turn to Electrolock for Polyester Heat Shrink Tape and More

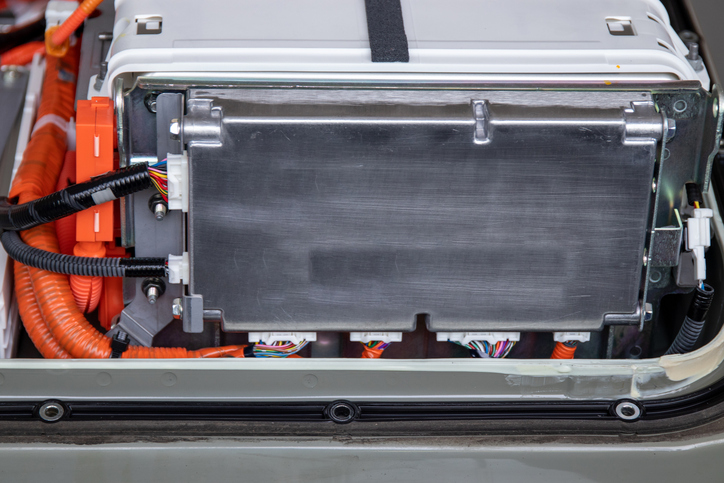

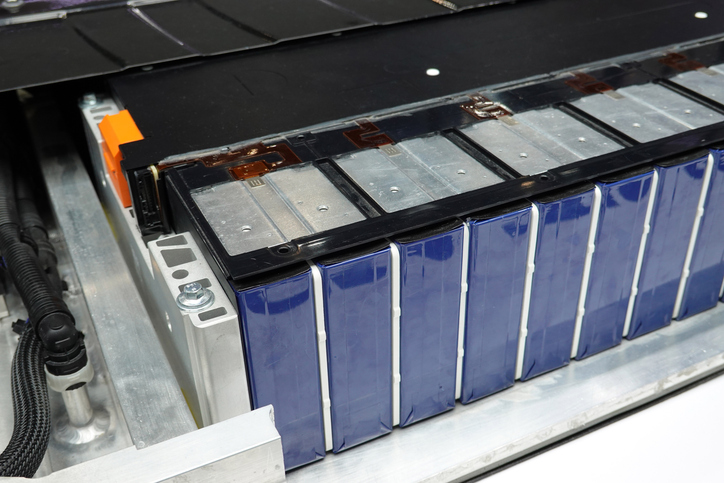

Electrolock has been engineering solutions for the high-voltage electrical, battery, and thermal insulation industries since 1957. Our focus has always and will continue to be focused on creating unique and tailored solutions to service the most demanding requests. From insulating motor and generator coils to wire and cable tapes, we have distributor relationships and engineering experience to find the right application solution for you.

From top-end, specialized lab equipment to the expertise-laden technicians and engineers conducting testing of insulation materials, Electrolock has the facilities and personnel required to find answers, validate selections, and create bespoke solutions.