Polyethylene terephthalate, or PET, is a clear, strong, lightweight plastic that is 100% recyclable. This versatile plastic has various applications in many industries, however, many of PET’s inherent properties make it a great choice for electrical insulation. Its high structural stability, electrical insulation, resistance to cracking, and low water absorption make PET insulation a popular replacement for metal electrical encapsulations. There are various insulation materials that are made from PET, each having its own unique properties and applications.

PET Insulation Materials

PET Layflat Tubes

PET layflat tubes are thin-walled, heat-shrinkable tubing or sleaving that provide physical strength and dielectric protection for electrical applications. Generally, this PET insulation material is implemented as a wear-resistant insulating cover for various products. And, since it is available in a variety of diameters, widths, and lengths, it can be designed to suit any necessary application or process requirements.

The most common application of PET layflat tubes is providing outside battery cell protection. These layflat tubes ensure that each battery cell is contained in its own module, protecting them from other cells. Outside cell protection is critical to the safety and functionality of the battery and is particularly important in electric vehicle (EV) batteries. Requiring extremely high amounts of energy to function, EVs use high-voltage batteries to store power. PET layflat tubes are used to protect each cell in these high-voltage batteries, allowing the batteries to continue to function properly.

PET Spiral Wound Tubing

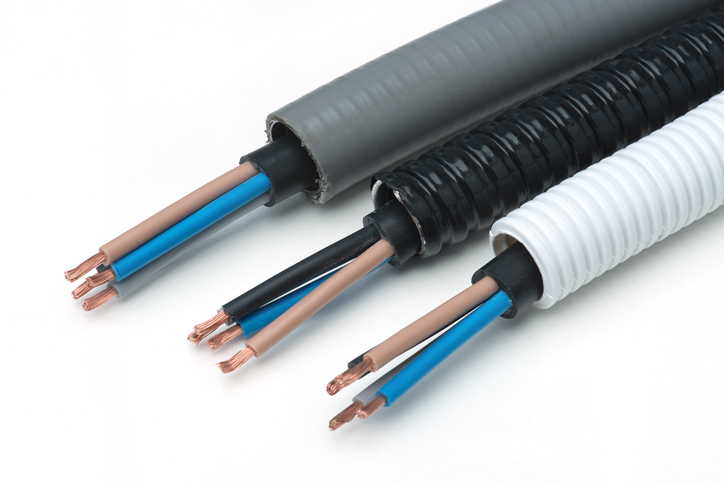

Expandable PET spiral wound tubing is designed to firmly hold wires while still allowing flexibility and easy access. This PET insulation material guards against abrasion and tearing while providing chemical and thermal protection. It can also add tensile strength, tear strength, and thermal conductivity to applications.

PET spiral wound tubing is typically in applications that need to meet electrical, thermal, mechanical, and chemical performance requirements. These instances include battery sleeves, wire connection insulation, and slot liners for EV motors.

Non-Woven PET Thermal Insulation Products

PET non-woven thermal insulation provides excellent strength, good air permeability, tensile strength, and tear resistance to various electrical applications. Non-woven PET insulation applications include electrical insulation, mica tape reinforcement, electrical laminated products, electric motor coil wrapping, and various cable insulation.

Needled Felt PET Thermal Insulation Products

Needled felt PET is characterized by its resistance to heat, tensile strength, anti-erosion properties, and exceptional electrical insulation. This PET insulation product is found in air conditioners, refrigerators, microwaves, and dishwashers as thermal insulation.

PET Polyshrink Film

PET polyshrink film is designed to apply the correct compaction force to electrical applications. It is designed to optimize compaction forces during the curing cycle of high-voltage coils and electrical composites. PET polyshrink film is largely used in the compaction of high-voltage coils, resin-rich coils, and wiring systems.

Electrolock Has All of the PET Insulation Materials for Your Project

For more than 60 years, Electrolock has been providing various types of electrical insulation products to our customers. From high-voltage insulation materials to battery insulation to Porex® tubing, Electrolock has the products and the expertise to match you with the right product for your application.

Our insulation materials have a wide range of applications, including battery insulation, coil wrapping, wire insulation, and so much more. When you work with us, we will help you determine the best product for your requirements and we will customize our products for you.

If you are interested in learning more about our products or services, or if you are ready to get started, contact us today.