Traditional Material Developing into Key Component for EV Protection

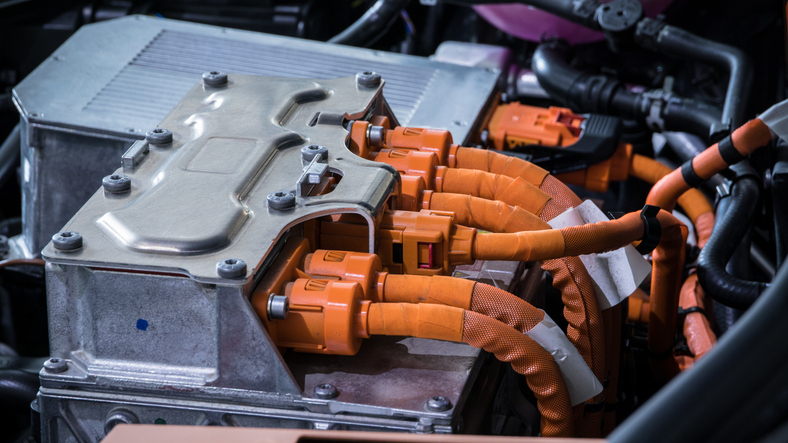

As the electrical vehicle (EV) market continues to expand and grow, there is more focus on developing new options for insulating and dissipating the heat from the battery packs used to power them. Mica plate battery insulation is becoming increasingly popular as an option for EV manufacturers in this area.

There’s no doubt that EV production has ramped up in the US. In 2022, 7% of all new vehicles produced were of the electric or hybrid variety. That number increased by nearly three percent from 2021, and more exponential growth in the second is expected. As more and more EVs hit the roadways, exploring optimal battery insulation solutions has become a priority for manufacturers.

Mica plate battery insulation has shown promise in addressing some of the lingering concerns surrounding battery usage in EVs. Temperature management is key as thermal runaway remains a potential threat in any device that relies on Lithium-ion batteries that power many of the devices, gadgets, and modes of transport used today.

We Provide Solutions: In this video, learn how Electrolock collaborates with customers to find the customized solutions they need to move the needle for their business.

What is Thermal Runaway?

Thermal runaway refers to the reaction that occurs when a battery reaches high temperatures and its thermal integrity is lost. At high temperatures, the components inside a single battery cell can ignite, releasing more heat which causes more cells to ignite causing a chain reaction. Once underway, it’s virtually impossible to stop a thermal runaway reaction.

The chances for such a reaction are increased due to excessive charging, rapid charging, short circuits within the battery, or unrelated fires that cause the battery to overheat. The process happens rapidly and can become uncontrollable very quickly. The reaction can damage the batteries beyond repair, and in a worst-case scenario, it can even destroy the EV, leading to potential personal harm.

In this area, battery insulation — covering a single cell, battery packs, and the entire system — is essential. Mica plate battery insulation can be used to line battery modules, protect bus boards, and line the inside of enclosures that house battery packs or the entire system. When lined with structural mica board or plate, these elements can buy the additional seconds needed to escape a vehicle in the event of a thermal runaway.

Mica Plate Battery Insulation Works for EV Applications

Mica, as a material, has long had a use in medium and high-voltage coil insulation systems. It can be used as a tape for high-temperature wire and cable insulation. In a plate form, mica delivers strong performance in shielding and acting as a thermal barrier for EV batteries — particularly in single-cell applications where it does an admirable job of containing the runaway element and flames inside a battery pack. In addition, mica plate is available at a much lower price point than other proven and effective solutions.

Mica plate won’t be a perfect fit for every EV application, however. It is heavier and more rigid than other materials and brings substantial heft to the insulation. With that in mind, mica plate battery insulation is best suited for multiple passengers and ground transportation applications. Its weight won’t be a detriment in an EV car or SUV but would be a negative for a drone or lightweight scooter, for example.

Explore Pyrodox HP5 Mica Plate

One of Electrolock’s premium mica plate battery insulation solutions is Pyrodox HP5, specifically designed for high-temperature applications. It has excellent mechanical, electrical, and thermal characteristics and has a flame classification of UL 94 V-0. Other key factors for HP5 include:

- Uses a high-temperature silicone resin as a binder

- Available in both Phlogopite (high temperature) and Muscovite (electrical resistance) versions

- Experiences less than 1% weight loss at 500℃

Electrolock also has the fabricating capabilities to mold this mica plate product into the form needed for specific EV applications.

- It’s available in a variety of thicknesses, ranging from 0.1mm up to 5mm.

- It can be applied with adhesives to stick to various housing components

- Die-cutting services allow for custom 2D shaping of the material

- CAD machining aids in mechanical attachment

Smooth Out Battery Insulation: Discover the benefits of PET layflat tubing for battery production. This heat-shrinkable, versatile element provides many use cases.

Discover Mica Plate Battery Insulation with Electrolock

Electrolock has been engineering solutions for the high-voltage electrical, battery, and thermal insulation industries since 1957. Our focus remains focused on creating unique and tailored solutions to service the most demanding requests. We have the distributor relationships and engineering experience to find the right application solution for you.

When exploring mica plate as an EV battery insulation solution, it’s important to remember that every battery module will be different — according to specific manufacturers and applications. It’s essential to rely on expert advice and testing to find the right product, and proper dimensions, for your specific application. How the material performs when on its own, as part of a backed product, or when placed on steel or aluminum are factors that must be considered.