Tailoring Your Material to Your Application is Critical

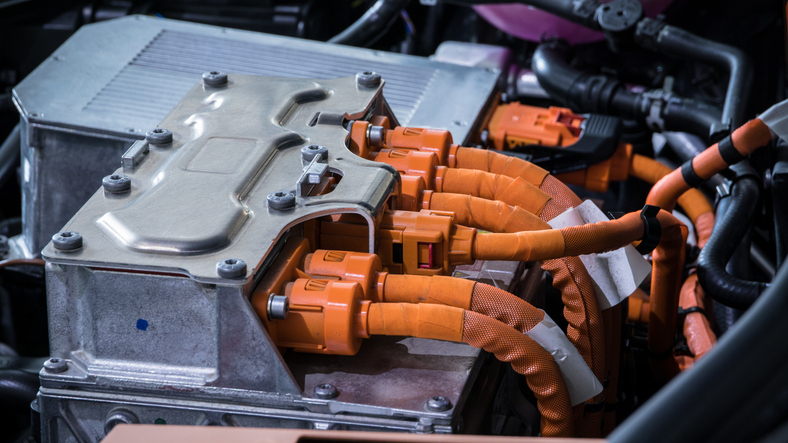

The world today runs on batteries, of many types and styles. Larger battery packs power electric vehicles (EVs), smaller lithium-ion or lithium polymer batteries fuel our cellphones and tablets and even ‘traditional’ batteries empower a plethora of hand-held devices. However, each of these use cases needs battery insulation material to help protect batteries from external factors, maintain optimal operating conditions, and prevent malfunction.

The variety in the type of battery insulation material is needed as various industries and applications have different requirements for battery protection. Today, we’re examining some of the most common materials used for such purposes and offering examples of the types of products implementing those materials for battery insulation purposes.

Need battery insulation solutions? We’re here to help: Reach out to Electrolock to learn how we design tailored insulation solutions, request a quote, or ask for a sample.

Reviewing Types of Battery Insulation Material

The following list provides a general overview of commonly used battery insulation materials. It’s important to note two things. First, this list is non-exhaustive and many of the materials can be configured into rigid, flexible, or semi-flexible solutions. Second, the specific insulation materials used in batteries can vary depending on the type of battery, its intended application, and industry requirements.

Polyester (PET) — PET offers good electrical insulation properties, high tensile strength, chemical resistance, and dimensional stability. It is often used as a separator material in batteries to prevent short circuits between the positive and negative electrodes. PET can also be used as a film or coating material for battery casings.

Polypropylene (PP) — PP is another popular choice for battery insulation due to its low electrical conductivity, good chemical resistance, and high-temperature tolerance. It is often used in battery separators.

Fiberglass — A composite made of fine glass fibers, this material helps as a thermal and electrical insulation material due to its high strength, resistance to chemical corrosion, and low thermal conductivity.

Mica — A natural mineral with excellent electrical and thermal insulating properties, Mica is often used as a separator material in batteries to prevent thermal runaway and improve safety.

Polytetrafluoroethylene (PTFE) — This non-stick material is known for its excellent electrical insulation properties, chemical resistance, and high-temperature tolerance. It is used in battery applications where chemical compatibility and electrical insulation are crucial.

Battery Insulation Material Solutions

The preceding list of materials can be used exclusively or combined to create ideal insulation solutions for battery applications. At Electrolock, we have expertise across a wide and diverse range of materials and use that knowledge to create battery insulation solutions that answer any challenge you face. Here’s a snapshot of several solutions we offer.

Heat Shrink Spiral Wound Tubes

Heat shrink polyester sleeving is used as a protective cover against abrasive or chemically harsh environments while also offering high dielectric protection, good tensile strength, and excellent chemical resistance. This sleeving will shrink in length and diameter when subjected to oven temperatures above 300°F or using a heat gun or similar heating device.

PET Layflat Tubing 740 HS

This lineal seal tubing comes as heat shrink sleeves with an extremely thin wall that provides both dielectric protection and physical toughness. The 740 HS is composed of a one-side, anti-static treated modified polyester (PET) film that is clear in color but can be printed on or colored. Formed into tubing, 740 heat shrink sleeves shrink quickly — roughly in 10 seconds at 100°C — and uniformly around cylindrical shapes.

Die-Cut Top & Bottom Cell Insulator

For inside the cell, dielectric barrier insulation, die-cut components are available in a variety of materials, including fiberglass, PTFE, PP, or PP. These are custom punched according to the specifics of the application.

Jelly Roll Wrap

This is a custom-designed dielectric barrier that fits between the jelly roll and the can of the battery. PET and PP, as well as polyimide, are commonly used here and often combined with a chemically-compatible adhesive for application.

For the jelly roll wrap and die-cut insulators, interested parties should contact Electrolock directly about technical specifications, availability, or samples.

What About Mica? Discover the strength of mica plate battery insulation and how it’s become a robust solution for EV applications.

Need Battery Insulation Material Expertise? Trust Electrolock

Every battery pack is different as each is designed specifically for its intended application. Therefore, each battery pack has different requirements for insulation placement and performance. This is where Electrolock can help. Finding the right materials for dielectric protection and thermal runaway and supplying the materials so that they fit in the limited insulation space in the pack is our specialty. Electrolock engineers try to understand all of these requirements and then submit the best material options for testing.

We have a vast library of material options and are not limited to any specific material choice. Once the customer approves materials, we provide the finished parts for use in the production of the packs.

Electrolock has produced premier custom insulation products, including the use of many spiral wound tubing materials, for the high voltage electrical, thermal insulation, and battery industries for more than 60 years. We have deep experience in working with any material to solve insulation challenges.