There are many calcined mica uses thanks to the material’s various beneficial properties. Calcined mica is non-flammable and has low thermal conductivity, making it a great insulation material. Calcined mica tapes are also very durable, which is useful in demanding situations.

Calcined mica tapes are designed to withstand high temperatures. At Electrolock, we take into consideration how the calcined mica tape functions in medium voltage applications, as well as applications in motors and generators.

In this blog, we’re taking a deeper look at calcined mica tape, including its properties and uses.

Why Use Calcined Mica Tapes?

Calcined mica tapes are designed to withstand tough applications and high temperatures. The calcination process is used to dehydrate the mica structure, which changes the mica papers that are eventually converted into mica tapes. These tapes are durable and provide excellent short-term dielectric breakdowns.

It should be noted that there are disadvantages to calcined mica tape, so it is not right for every application. Mica paper that is not calcined is commonly referred to as uncalcined mica paper. Before dehydrating the mica crystals there are still excellent electrical and thermal properties, however, the calcination process usually yields a smaller mica flake. This smaller flake can have tighter cross-sheet toughness, but at the same time requires more time for resins to penetrate. Uncalcined papers typically absorb resin faster even though they are more fragile to work with. Manufacturers should discuss the tradeoffs; this can be critical in a medium or high-voltage application.

For manufacturers that have already decided they need a calcined mica tape, there are still several options to choose from depending on the application. These mica papers, calcined or uncalcined, are bonded to carriers such as glass, polyester, or polyimide. A binding resin is included to keep the mica paper and the carrier from separating. Binder resins are far weaker thermally than mica paper and can ultimately decide which tape is correct for your application.

Properties and Common Calcined Mica Uses

Many calcined mica properties make it a strong material option. It provides excellent insulation due to its non-flammable nature and low thermal conductivity. Calcined mica tape is durable and because it typically has a higher binder content it can be easier to apply during the taping process. Let’s delve a little further into its other beneficial qualities.

High Temperature Resistance

During the manufacturing of this tape, the calcined mica is dehydrated to give it a better structure. In doing so, the calcined mica tape becomes stronger and more durable, giving it the ability to resist high temperatures.

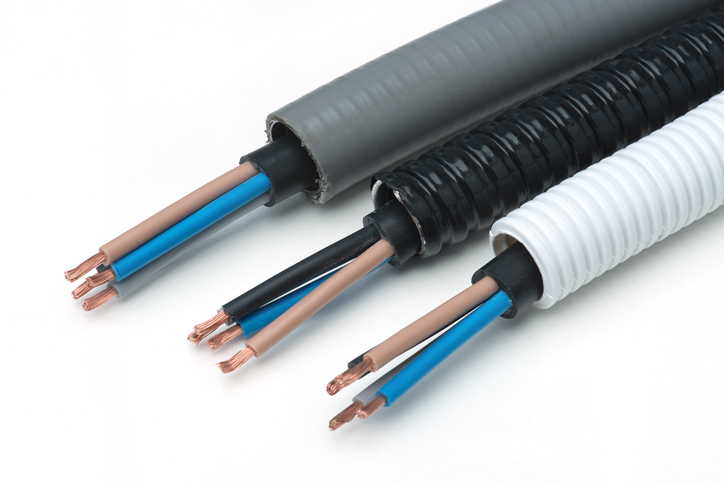

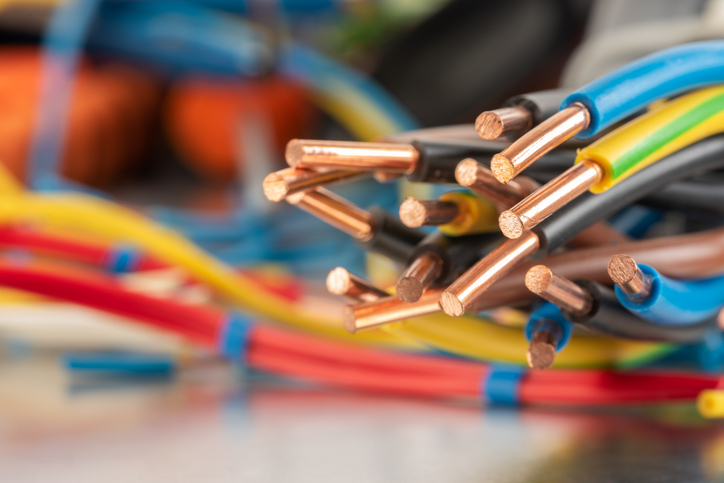

Wire and Cable Insulation

In order to prevent electrical leakage, wires and cables must be properly insulated. Using calcined mica as this insulation material prevents this electrical leakage, preserves the integrity of the wire, and makes the wires and cables safe and effective.

Motor and Generator Coils

A crucial aspect of motor and generator coils is insulation. To prevent the electrical current from passing between coils or escaping the coils, proper insulation materials need to be used. Calcined mica can withstand the voltage and heat of the generators, making it a great insulation material for the wires within motor and generator coils.

If You Have Calcined Mica Uses, Turn to Electrolock

For nearly seven decades, Electrolock has been engineering and manufacturing insulation materials for various applications. Our team understands how to create insulation materials for high-voltage applications, batteries, wires and cables, high-temperature applications, and motor and generator coil insulation.

Calcined mica tapes are designed to withstand high temperatures. We take into consideration how the calcined mica tape functions in medium-voltage applications, as well as applications in motors and generators.

In addition to our ability to create calcined mica tape, we create high-voltage insulators, battery insulation, spiral wound tubing, polyshrink film, and more. We also offer many services to ensure you receive the best product possible for your application.

Our team can test your insulation materials with analytical and high-voltage testing to determine the functionality of the product. If you don’t find the right solution off the shelf, we can design, engineer, and manufacture a solution that meets all of your needs.

If you are ready to see what we can create for you, contact our team today.