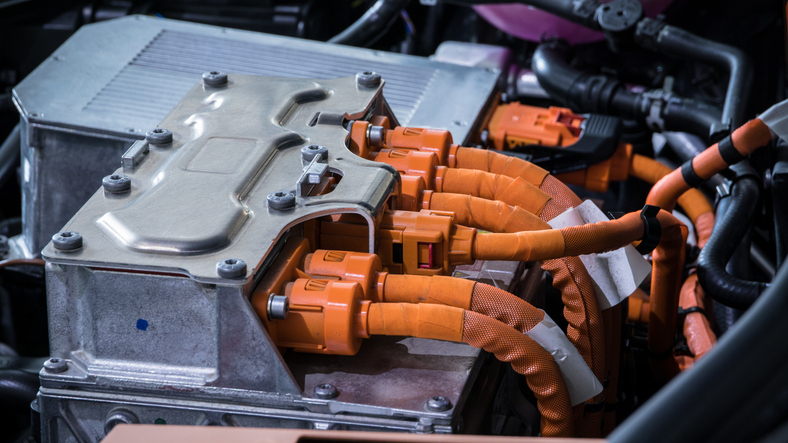

Insulation solutions are crucial for a range of applications. From high-voltage electrical to batteries to thermal insulation, these solutions not only need to function properly, but they also need to fit.

Die-cutting is a manufacturing process in which a machine uses a metal component called a die to cut specific shapes from a material. It is primarily used to create customized solutions quickly and easily, including die-cut insulators.

What are Die-Cut Insulators?

Die-cut insulators are custom-made insulation solutions. Insulators hinder the free flow of electrons and eliminate the unintended discharge of the electric current. These insulators are also used to reduce the amount of heat produced by a battery or electrical application and improve functionality.

Benefits of Die-Cut Insulators

Customization

Die-cutting allows your insulation manufacturer to create your solutions in exactly the shape and size you need. This will save you time and money down the line, as you won’t have to perform these actions yourself.

Uniformity and Reproducibility

The dies used are made from metal, making them extremely durable. This allows the die to be used repeatedly without breaking down. So, the same die can be used over and over to produce die-cut insulators that are exactly the same as many times as you need.

Complex Designs

Having to try to hand-cut insulators to meet the needs of your complex-shaped products is time-consuming and tedious. By choosing die-cut insulators, you eliminate the need to do this by hand. Plus, dies can be manufactured into nearly any shape, accommodating even the most complex of designs

What Die-Cut Insulation Options Are There?

Many different insulation options can be customized through die-cutting, however, most of these include mica tape, wire and cable insulation tape, silica tape, and cell wrappers.

Mica Tape

This insulation option includes mica paper that is laminated to various substrates. Due to mica’s high dielectric strength, low electric loss, and excellent thermal stability, it is a great choice for high-voltage applications, wire and cable insulation, and thermal insulation.

Wire and Cable Insulation Tape

These insulation solutions must withstand high temperatures and demanding environments. Mica tapes are used in these applications, however, Kapton® and Nomex® are also used due to their high-temperature resistance and electrical insulation properties.

Thermal Insulation Solutions

These solutions are used to prevent thermal runaway in batteries and protect heat-sensitive products. Thermal insulation solutions include non-woven fiberglass paper, silicone-coated fabrics, and more.

Electrolock Is Here to Help Innovate Your High Voltage Insulation Solutions

Electrolock has been engineering high-voltage, battery, and thermal insulation solutions since 1957. We can provide you with various types of electrical insulation, including high-voltage solutions, battery insulation, and more.

If you can’t find a solution that meets your needs, our team will work with you to design and manufacture a solution that fits your specifications. We can identify your problem and manufacture a solution that fits your needs. Then, we can perform analytical testing to make sure that these solutions truly meet all of your needs.

Contact our team today to get started.