Electrical insulation plays a fundamental role in the safety, efficiency, and reliability of industrial operations. From high-voltage equipment to battery systems and thermal management, proper insulation is crucial for protecting both equipment and personnel. Below we’ll explore the importance of electrical insulation to help those who need to make informed decisions about their equipment and processes gain a better understanding of the core principles and applications involved.

Custom Solutions for Your Specific Applications: Reach out to the Electrolock team today to begin discussing your next electrical insulation project.

Fundamental Principles of Electrical Insulation

At its core, electrical insulation serves to prevent the uncontrolled flow of electrical current between conductors. In industrial applications, this means containing electrical energy within its intended path while protecting surrounding components and operators. Effective insulation materials must demonstrate specific properties including high dielectric strength, thermal stability, and mechanical durability. These characteristics become particularly critical in environments with extreme temperatures, high voltage loads, or constant mechanical stress.

The Importance of Electrical Insulation for Critical Applications in Modern Industry

High-voltage applications demand precise insulation solutions to maintain operational integrity. Power distribution equipment requires carefully engineered insulation systems to prevent electrical breakdown and ensure consistent performance. Industrial machinery often operates under demanding conditions where insulation failure could lead to equipment damage or workplace hazards. Professional-grade insulation materials and proper installation methods are essential for maintaining safe, efficient operations.

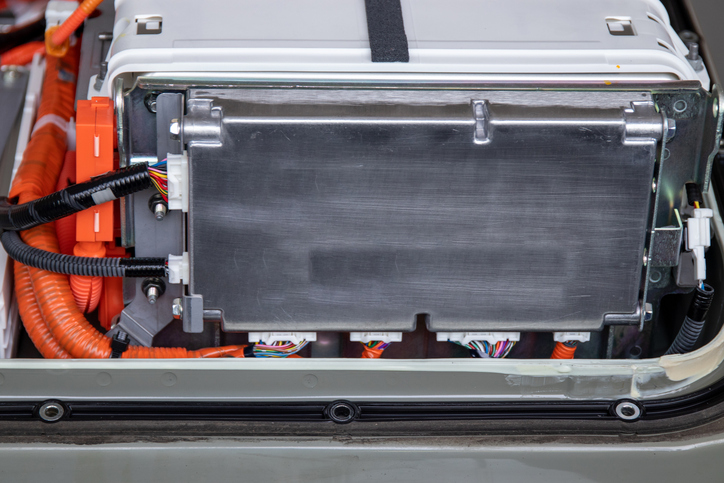

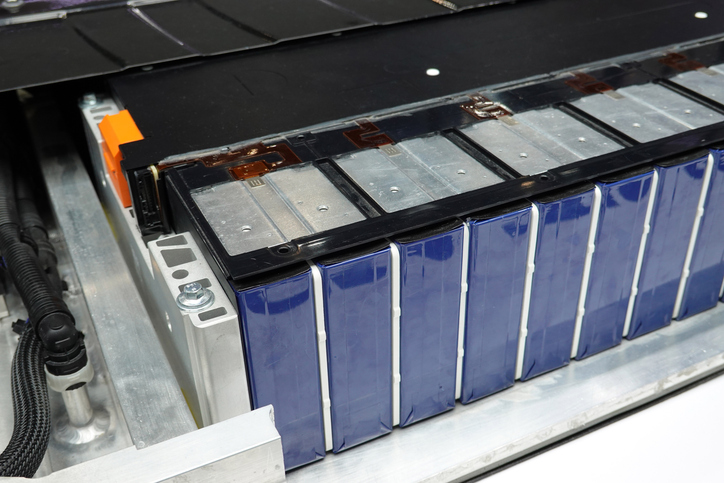

Battery technology presents unique insulation challenges, particularly in electric vehicle applications and industrial energy storage systems. Effective battery insulation must address both electrical and thermal concerns. Proper insulation in battery systems prevents short circuits, manages cell-to-cell thermal transfer, and helps maintain optimal operating temperatures. This dual functionality makes material selection and design particularly critical for battery applications.

Thermal protection represents another crucial aspect of industrial insulation. Many industrial processes generate significant heat that must be managed to protect equipment and maintain efficiency. Thermal insulation works alongside electrical insulation to create comprehensive protection systems. This integration is particularly important in applications where electrical equipment operates at high temperatures or where thermal runaway could pose serious risks.

Choosing the Right Insulation Solutions

Selecting appropriate insulation materials requires careful consideration of multiple factors. Operating temperature range, voltage requirements, mechanical stress, and environmental conditions all influence material selection. Standard insulation products may suffice for common applications, but many industrial processes benefit from customized solutions that address specific operational challenges.

Material options range from traditional mica tapes and process films to specialized composites designed for extreme conditions. Each material offers distinct advantages in terms of temperature resistance, dielectric strength, and mechanical properties. Professional consultation often proves valuable in matching insulation materials and designs to specific application requirements.

High voltage testing plays a crucial role in validating insulation performance. Proper analytical testing can verify dielectric strength, thermal resistance, and mechanical durability under simulated operating conditions. These tests help ensure that selected materials will perform reliably in real-world applications and meet required safety standards. Regular testing throughout the development process helps identify potential issues before they become operational problems.

At Electrolock, We Believe in the Importance of Electrical Insulation

Proper electrical insulation stands as a cornerstone of industrial equipment reliability and safety. Whether dealing with high-voltage systems, battery applications, or thermal management challenges, choosing the right insulation solution directly impacts operational success.

Electrolock brings decades of experience in developing and manufacturing high-performance insulation solutions for demanding industrial applications. With comprehensive capabilities in material selection, custom design, and high-voltage testing, Electrolock partners with clients to create optimal insulation solutions for their specific needs. From standard products like mica tapes and process films to custom-engineered solutions for unique applications, Electrolock’s technical expertise ensures reliable performance in critical industrial operations.

Contact Electrolock’s engineering team to discuss your specific insulation requirements and discover how our testing and manufacturing capabilities can support your operational success.