Precision is essential when working with insulation applications, and rotary die-cut custom insulation solutions provide the repeatable, exact-detail orientation needed to execute those applications at a high level of efficiency.

Let’s examine the aspects of rotary die cutting, and why it makes sense as a manufacturing method for insulation solution — complete with a specific example drawn from the suite of services offered at Electrolock.

What is Rotary Die Cutting?

A die, in the simplest terms regarding manufacturing or crafting, is a tool used to cut material into a given shape. Die-cutting is a fabrication process that uses specialized tools to convert stock materials into custom shapes and designs by cutting, forming, and shearing products from sheets or rolls of materials.

There are also several different types of die-cutting processes available, including digital die-cutting, flatbed die cutting, and rotary die-cutting. Flatbed die cutting uses a flat cutting press and custom steel dies to convert the material into shapes and designs. This process is utilized for thicker materials, larger parts, and for short production orders or small orders. Digital die-cutting eschews dies altogether, and instead uses computer-guided lasers and tool bits to provide the cuts. This process will have high tolerances for more intricate design patterns and is best suited for small production runs or prototyping as it doesn’t require new die components to test out new designs.

However, rotary die cutting offers the capabilities needed for custom insulation solution manufacturing. This process works by employing a custom cylindrical die (or multiple dies) to cut against a hardened anvil roll with the material to be cut and formed passing between those two components. When you need high precision and accuracy in your application and will have a high-volume production run, this method is the best option.

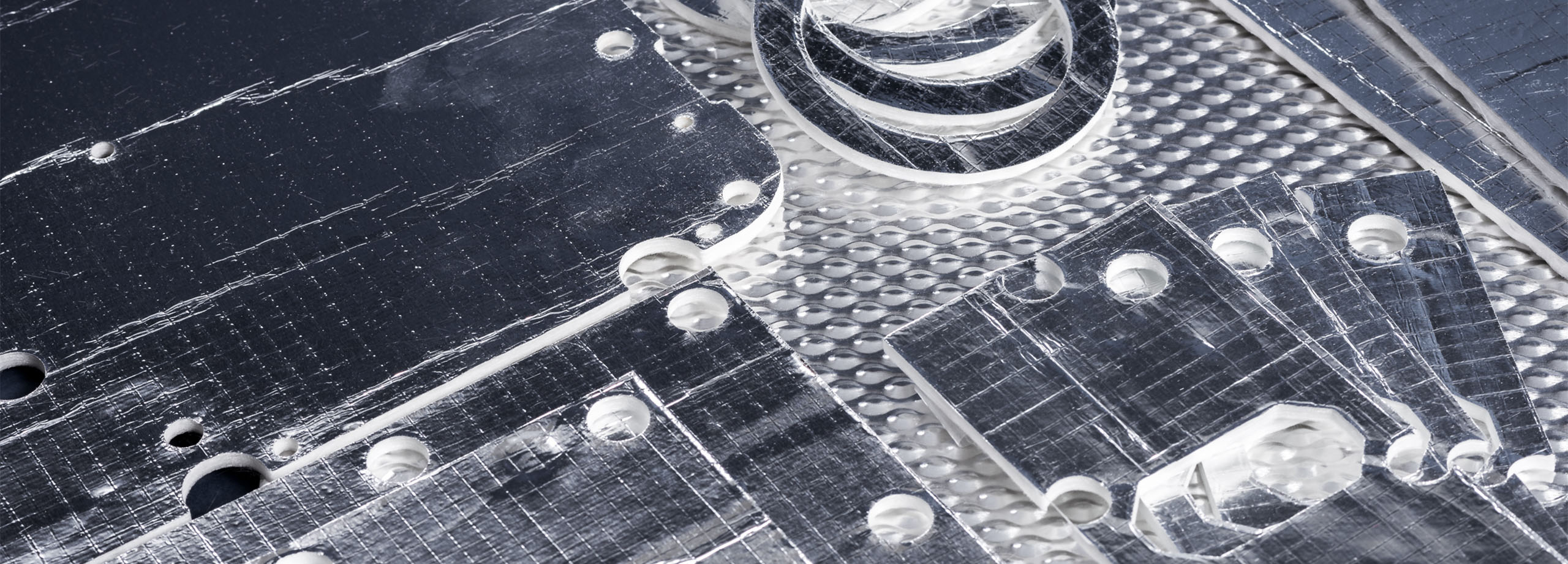

In the pursuit of both precision and speed, rotary die-cut custom insulation solutions provide the most efficient path forward. Rotary die cutting provides uniformity for complex shapes, which are often needed when dealing with the many kinds of materials used in battery insulation applications. A rotary die-cut fabrication process can create many cuts of any given material that are consistently within tolerance limits, which is essential to every manufacturing project. With the design engraved into the die, parts are easily reproduced and the precision in this process also reduces material waste as the die-cut designs can be more tightly placed together.

Rotary dies can be swapped out within presses, which shortens the downtime between different designs and processes. Rotary dies can also handle multi-layered materials and complex designs. For example, multiple materials can be laminated together and die cut at the same time, or sensitive adhesives can be applied so die-cut parts can be supplied on a liner — all of which saves time and money. Rotary die-cut fabrications are ideal for engineering, which needs layers of different materials to be precisely the same size.

Want to know more about Electrolock? Read about their engineered solutions here.

An Example of a Rotary Die Cut Custom Insulation Solution

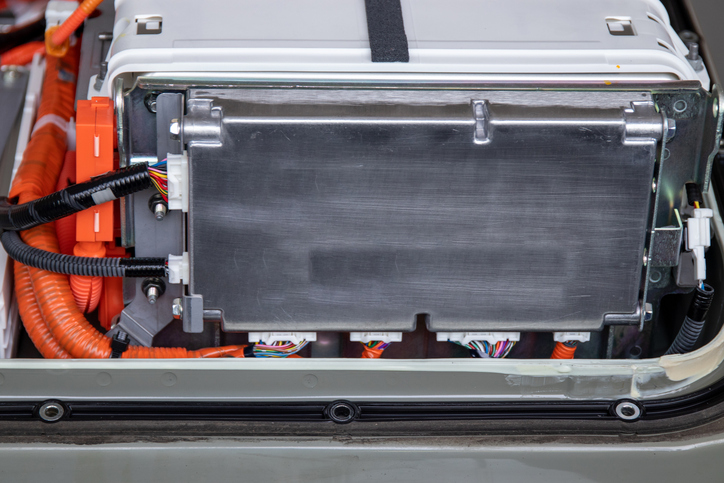

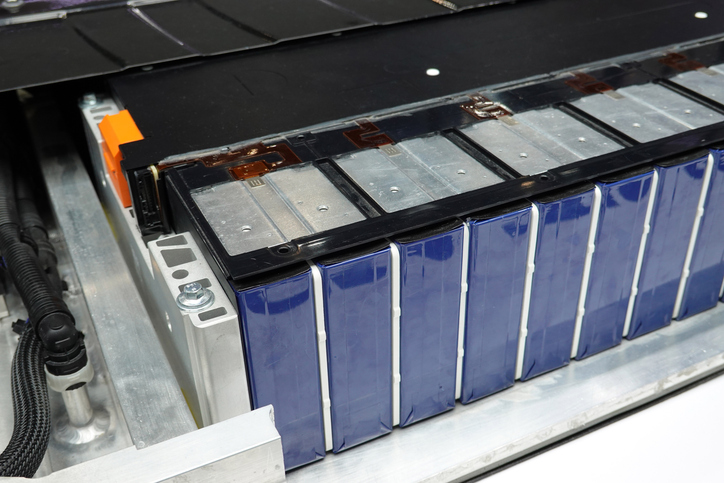

A good case in point of using rotary die-cutting in practice at Electrolock involves the production of Top and Bottom Cell Insulators, which are just one of the many solutions available in the realm of battery insulation.

These dielectric barriers are designed to protect individual cells, and for cell-to-cell protection, with thin wall die-cut pressure-sensitive parts made of flame-retardant films or papers. Depending on the material used, up to 15 Kv protection can be achieved. An array of materials can be used — such as fiberglass, PTFE, Polypropylene, or PET insulations — and all materials can be instituted with or without adhesive.

Rotary die-cutting is a strong choice for this manufacturing solution due to the uniformity required for each of the specific units. Rotary die cutting also enables that precision to hold through the many different types of material that may be implemented, and — with the possible addition of adhesives — the ability to address or cut and form more than one layer of material at a time. Top and Bottom Cell Insulators are one of the rotary die-cut custom insulation solutions available.

Electrolock Offers Much More

Electrolock has been engineering solutions for the high-voltage electrical, battery, and thermal insulation industries since 1957. Our focus has always and will continue to be, focused on creating bespoke — unique and tailored — solutions to service the most demanding requests.

By choosing Electrolock, you won’t simply be picking a product from a catalog or menu of options. You’ll work with Electrolock’s experienced, expert-level team to create a custom-designed answer to your particular problem.

By collaborating with your business, Electrolock will design, fabricate, and then fully test potential solutions. By validating — through an extensive in-house testing system — before entering production, Electrolock is able to save both time and expense on the back-end of a project.

No matter what your material or insulation challenge, Electrolock will help you solve it.

Contact us today to schedule a one-on-one consultation or evaluation on your material needs or application specifics.