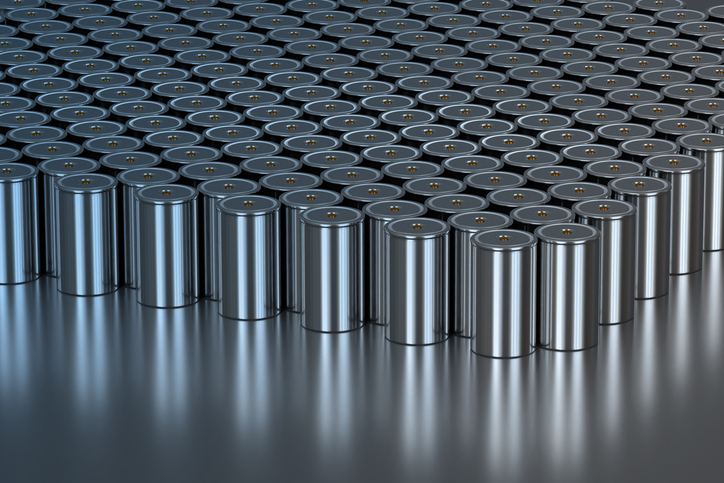

The growing demand for efficient, safe battery systems has placed increased focus on battery cell insulation materials. Proper insulation plays a crucial role in battery performance, longevity, and safety. Understanding the characteristics and applications of different insulation materials helps engineers and manufacturers select optimal solutions for their specific requirements.

Today we’re taking a closer look at different types of materials and in what cases they could serve as the ideal solution for your battery cell insulation needs. Let’s get started.

Creating Bespoke Insulation Solutions is What We Do: Reach out to the Electrolock team today to begin discussing your next electrical insulation project.

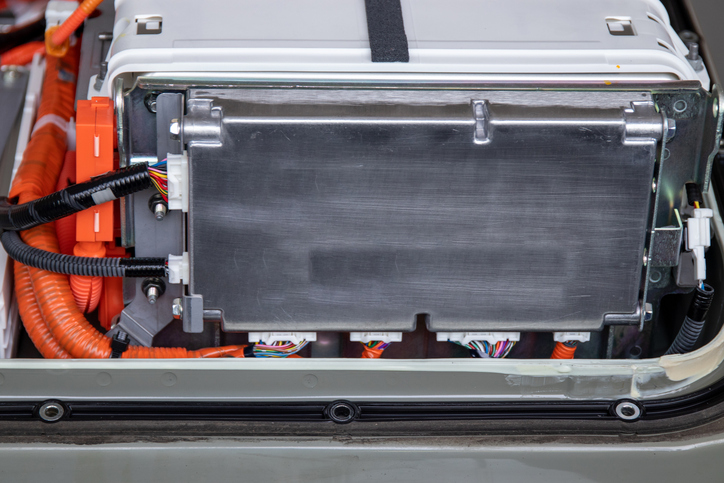

Core Functions of Battery Cell Insulation

Battery cell insulation serves multiple critical functions in modern battery systems. These materials must provide reliable electrical isolation between cells while managing thermal transfer and offering mechanical protection. Effective insulation prevents short circuits, helps maintain optimal operating temperatures, and protects against physical stress during normal operation and potential failure events — such as thermal runaway.

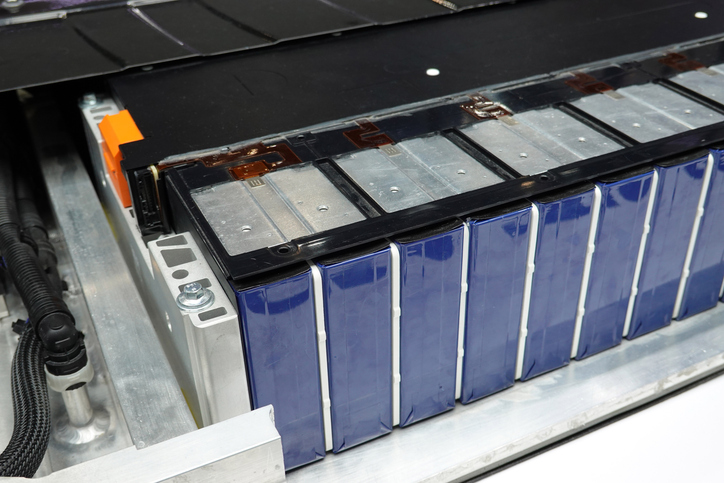

Mica-Based Insulation Materials

Mica stands out in battery applications due to its exceptional electrical insulation properties and thermal stability. This natural mineral-based material maintains its insulative properties at high temperatures and offers excellent resistance to electrical tracking. Mica-based solutions prove particularly effective in applications requiring extended exposure to elevated temperatures.

Key advantages of mica include its high dielectric strength, flame resistance, and dimensional stability. These properties make it ideal for high-power battery systems where thermal management is critical. While mica solutions may carry a higher initial cost compared to some alternatives, their durability and reliable performance often justify the investment in demanding applications.

PET-Based Solutions

Polyethylene terephthalate (PET) insulation materials offer a balanced combination of performance and cost-effectiveness. These materials provide good electrical insulation properties and mechanical strength while remaining lightweight and flexible. PET solutions adapt well to various cell formats and manufacturing processes.

PET insulation materials demonstrate strong chemical resistance and maintain stability across a moderate temperature range. Their cost-effective nature and ease of integration make them particularly suitable for medium-duty applications where extreme temperature resistance isn’t critical. PET’s versatility allows for various manufacturing methods, including custom-shaped barriers and sleeves.

Ceramic Insulation Options

Ceramic insulation materials excel in extreme temperature environments and applications requiring superior thermal management. These materials offer exceptional heat resistance and can maintain their insulative properties under severe conditions. Ceramic solutions particularly suit high-stress applications where thermal runaway prevention is paramount.

While ceramic materials typically represent a higher-cost option, their unmatched thermal properties and longevity prove valuable in critical applications. Their rigid nature requires careful consideration during the design and integration phases, but their reliability in extreme conditions often outweighs these challenges.

Battery Cell Insulation Selection Criteria and Considerations

Choosing the optimal insulation material requires careful evaluation of several factors. Here’s a quick checklist of considerations you should have in mind before selecting a specific material:

Operating Environment

- Maximum and minimum temperature requirements

- Exposure to chemicals or contaminants

- Mechanical stress levels

Performance Requirements

- Dielectric strength needs

- Thermal conductivity targets

- Required service life

- Safety standards compliance

Manufacturing Considerations

- Integration with existing processes

- Material handling requirements

- Production volume implications

- Total cost of ownership

For Battery Cell Insulation and Much More, Turn to Electrolock

Selecting the right battery cell insulation material significantly impacts system performance, safety, and cost-effectiveness. While mica offers superior thermal stability and electrical isolation, PET provides cost-effective solutions for moderate applications, and ceramic materials excel in extreme conditions.

Electrolock’s extensive experience in battery insulation materials enables informed guidance through the selection process. Our engineering team works directly with clients to analyze application requirements and recommend optimal solutions, whether standard or custom. We maintain comprehensive testing capabilities to validate material performance under specific operating conditions.

Contact Electrolock to discuss your battery cell insulation needs and leverage our expertise in material selection, testing, and custom solution development. Our technical team can help ensure your insulation choice aligns with both performance requirements and operational constraints.