Modern industrial operations and electric vehicle applications demand increasingly sophisticated motor coil insulation systems. As power densities rise and operational environments become more challenging, the role of proper insulation in ensuring motor reliability and efficiency becomes ever more critical. Understanding current advancements in insulation technology helps engineers and manufacturers optimize their motor designs for peak performance.

Since 1957, Electrolock has developed innovations that have played a crucial role in improving coil performance. Today we’ll take a closer look at motor coil insulation and the types of solutions we use to create ideal insulation solutions.

Creating Bespoke Insulation Solutions is What We Do: Reach out to the Electrolock team today to begin discussing your next electrical insulation project.

Key Components of Modern Motor Coil Insulation

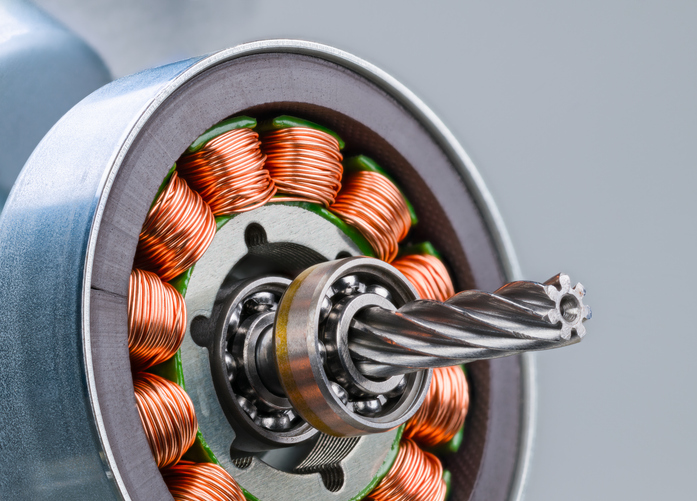

Today’s motor coil insulation systems integrate multiple protective elements to ensure reliable operation. Ground wall insulation systems, typically incorporating high-performance mica tapes, provide fundamental electrical isolation while maintaining thermal stability. Corona suppression solutions, essential in high-voltage applications, prevent partial discharge damage and extend motor life. Phase insulation and conductor protection complete the system, ensuring comprehensive protection throughout the motor assembly.

Advanced Material Solutions

Recent developments in insulation materials have significantly expanded design possibilities. Mica-based solutions continue to excel in high-voltage applications, offering superior dielectric strength and thermal stability. When properly engineered, these materials optimize ground wall thickness while improving voltage endurance.

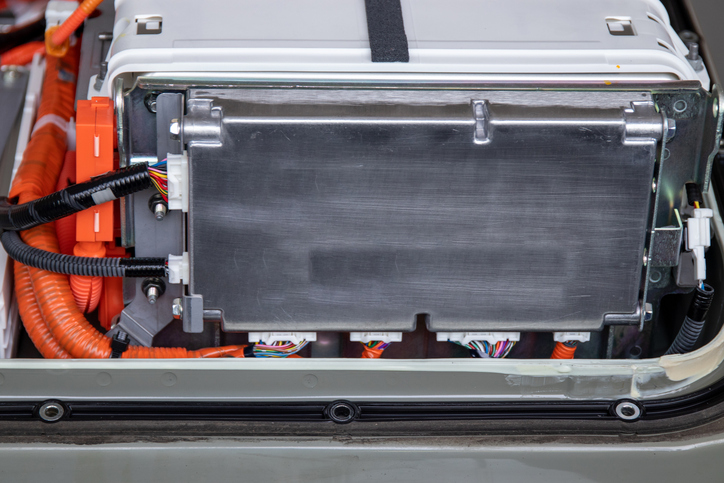

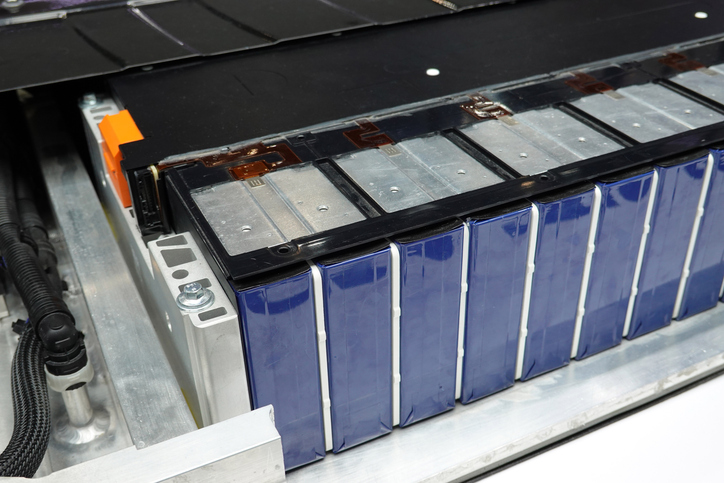

High-performance polymers, including Nomex® and Polyimide materials, provide exceptional mechanical strength and thermal resistance. These materials prove particularly valuable in applications requiring continuous operation at elevated temperatures, such as electric vehicle motors. Combining multiple materials, composite systems can be engineered to address specific operational challenges while maintaining optimal performance characteristics.

Critical Performance Factors for Motor Coil Insulation

Successful motor coil insulation design requires careful consideration of multiple performance factors. Thermal management capabilities must account for continuous operating temperatures and temporary excursions during peak loads. Voltage endurance characteristics ensure reliable operation throughout the motor’s service life, while mechanical strength protects against vibration and physical stress.

Environmental protection has become increasingly important, particularly in applications where motors operate in challenging conditions. Modern insulation systems must resist chemical exposure, moisture infiltration, and other environmental factors while maintaining their core protective properties.

Implementation and Quality Assurance

Selecting and implementing appropriate insulation solutions requires a systematic approach. Material selection must consider not only electrical and thermal requirements but also manufacturing processes and cost constraints. Comprehensive testing programs, including electrical, thermal, and mechanical validation, ensure that insulation systems meet performance requirements under actual operating conditions.

Custom solution development often proves valuable when standard materials cannot fully address application requirements. This process involves careful analysis of operational parameters, material capabilities, and manufacturing considerations to create optimal insulation systems for specific applications.

Electrolock: Supporting Your Success with Motor Coil Insulation

Electrolock brings extensive experience in developing and implementing advanced motor coil insulation solutions. Our comprehensive range of materials, from mica tapes and ground wall insulation to corona suppression systems and phase protection materials, enables the development of optimized solutions for specific applications.

Because Electrolock covers every aspect of motor and high voltage insulation, it can address all the major processes used in constructing coils — and find the right insulation system and products to ensure their operation.

Our engineering team partners with clients throughout the development process, from initial material selection through final implementation. This collaborative approach, combined with our testing and manufacturing capabilities, ensures that insulation solutions meet both performance requirements and practical constraints.

Contact Electrolock to discuss your motor coil insulation requirements and discover how our materials expertise can enhance your motor design’s reliability and efficiency.