High-temperature laminates provide additional characteristics to parts and materials, while also ensuring their performance in applications where heat and thermal resistance is critical. In general terms, lamination is the technique or process of manufacturing a material consisting of multiple layers; This composite material, or the part it is applied to, will then have improved characteristics. These characteristics range across a full spectrum of abilities, from improved strength and stability, sound insulation, and appearance, to improved resistance against potentially disruptive factors like an electrical current, high temperatures, or chemicals.

Electrolock applies its approach of finding bespoke solutions to specific applications faced by our customers. In this way, designing, manufacturing, and implementing laminates — and in particular high-temperature laminates — is an essential part of what Electrock does from its two North American locations.

For instance, using laminating you can add foil-faced materials to use on a high-temperature gasket. You could include a laminate with an absorbent outer layer for use on a component that needed to remain dry or avoid moisture. You can laminate a part or cutout to apply an additional adhesive to give the finished product a peel & stick capability. With the right production combination, you can combine several needs into one laminate; For example, you could add a static dissipating layer to a laminate already consisting of a dielectric layer and a thermal isolation layer — then have the entire composite backed by an adhesive.

Electrolock will consult with you to find the right combination to serve the demands of your specific application, and has extensive experience in working with high-temperature laminates. Electrolock has the ability to work with high-temperature films, thermoplastics, fabric substrates, and high-temperature adhesives for laminates that are effective up to 525°F. Other laminate options to note include:

- Electrolock can design laminates with multiple substrates, up to six layers

- Electrolock is experienced with many laminate materials, including polyimides, fiberglass, foils with glass backing, and brand options like Kevlar®

- Electrolock has expertise with a wide range of adhesives, including various acrylics, phenols, polys (polyurethane/polyesters), epoxies, and fluoroelastomers

With these capabilities, Electrolock can devise and manufacture the laminate your application demands. Below are just three of the many possible examples of Electrolock providing high-temperature laminate solutions.

Looking for tape instead? Electrolock also has shrink and release tapes to facilitate the processing of high-voltage coils and composites. Learn more here.

3 Examples of High-Temperature Laminates

CraneGlas®

CraneGlas is a nonwoven fiberglass paper made from fine diameter electrical grade fibers of uniform length, with a PVA binder. The paper is capable of operating at high temperatures, is flame retardant, and is available in a range of thicknesses. It can be supplied slit to your required width with a wide variety of put-ups.

CraneGlas can be implemented in many different applications, including chemical trace lines, thermal gaskets, battery separators, and photovoltaic panels. It can also be used, as a layer in copper-clad laminate, for printed wiring boards.

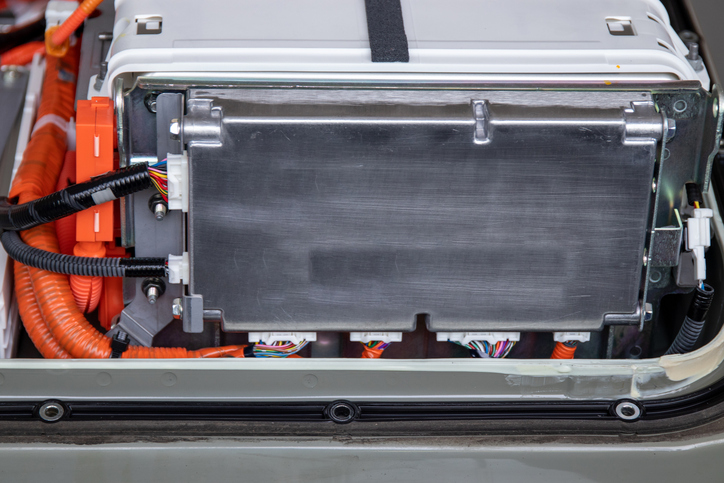

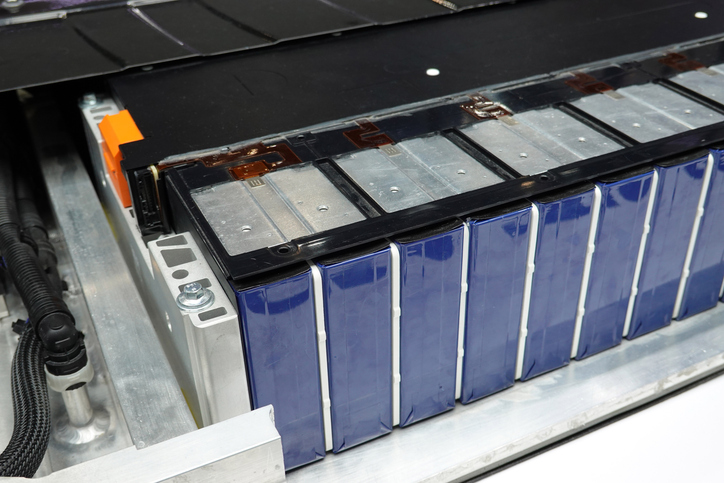

Go-Therm Thermal Runaway Barrier

Go-Therm is a highly flexible, silicone-based barrier designed for use as an interior lining in a battery case. It provides superior performance to protect the pack from the ejecta and flames caused by an incident of thermal runaway. More flexible than rigid mica plate, Go-Therm can also be used as a thermal runaway barrier between prismatic cells in a single module. Parts can be fabricated to size and are available with a pressure-sensitive adhesive on one side.

Go-Therm comes in two types. Go-Therm 150 is a glass one-side silicone laminate. Go-Therm 315 is a fiberglass-backed (both sides) 1.5mm thick laminate.

Keveloc®

Keveloc is a puncture-resistant laminate designed to provide cut-through or puncture resistance to areas under compression pressure or shear forces. Keveloc is a barrier insert that withstands operating temperatures for Class F or Class H machines — winding insulation max temperatures of 155°C and 180°C respectively — and is typically employed as a crossover barrier for roebel conductors in high voltage coils.

Available in a thickness of just .015”, Keveloc still has a robust tensile strength (175 pounds/inch width) and shear puncture resistance (1,381 lbs.).

Explore Our Battery Solutions: Electrolock covers every aspect of battery insulation, from dielectric barriers to thermal runaway protection. See more here.

Trust Electrolock with Your High-Temperature Laminates

Electrolock has been engineering solutions for the high-voltage electrical, battery, and thermal insulation industries since 1957. Our focus has always and will continue to be focused on creating unique and tailored solutions to service the most demanding requests.

Electrolock has extensive experience working with multiple materials to design the right laminate for your application, produce that laminate, then add finishes to aid in application use. Our complete line of manufacturing services can slit the material to the necessary width, produce punched parts, add pressure-sensitive adhesive, enable die-cutting, and much more.

Electrolock has the capability to produce roll-to-roll lamination for a large swath of industries, including battery insulation, automotive, motor generator coils, and many aspects of the electronics sector. With roll-to-roll lamination, you’ll receive continuous, consistent delivery of the material leading to a more efficient and cost-effective process.