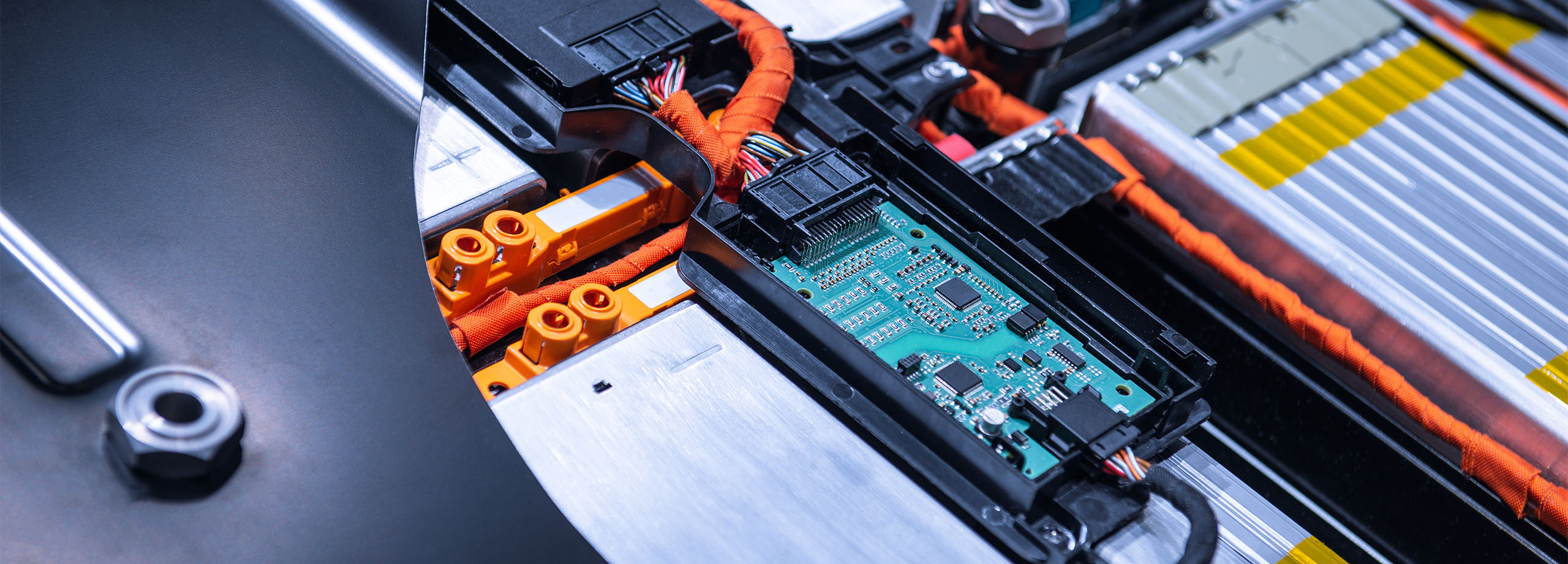

It’s a story all too familiar—cells overheating, causing thermal runaway, putting companies in the spotlight for all the wrong reasons. Despite these risks, we rely on batteries to power everything from our cell phones to electric vehicles to military munitions and downhole drilling equipment. Safety starts with battery insulators.

Thin wall die-cut pressure-sensitive parts made of flame retardant films or papers provide excellent protection on or between cells. Depending on the material used, up to 15 Kv protection can be achieved. Dielectric shrink sleeves are also custom-designed for the cylindrical, pouch, or prismatic cells and can provide up to 5Kv protection for each cell. Products can be supplied in high or low shrink versions and can be supplied as a sleeve or a pouch. Alternative non-shrink materials can also be used to provide extreme temperature and flame resistance.

Products can be fabricated to custom shapes and have thermal conductivity as low as .13 W/mK. Materials can be supplied with pressure-sensitive adhesives or laminated to another insulating material. Electrolock also provides flame retardant thermal sleeves, designed to be applied directly over cylindrical cells that provide excellent thermal and flame resistance.

With extremely limited space for insulation protection, what are the best options for reducing cell-to-cell flame spread? How can the extreme heat from one cell be limited in spreading to the adjacent cells? How do you stop the chain reaction of thermal runaway once a single cell vents or ruptures?

Electrolock supplies various thermal runaway insulation materials, like battery insulation wraps and sleeves and our Go-Therm Thermal Runaway Barrier, that limit the spread of flame and heat during a thermal runaway event. As with all of our insulation material choices, our engineers try to understand the requirements of your specific battery pack and try to choose the best options for testing in the limited space available. These materials can be a combination of flame and thermal barriers or strictly a thin wall, flame resistance part. After you test and approve the material options, we can provide the finished parts fabricated to the required dimensions.

We work with our customers’ engineering group to define all the requirements that the battery insulator needs to meet, then choose the correct materials to maintain safe performance.

Attention to detail during each step of the insulation design phase. We design finished parts that will process in your equipment, perform exactly to specification, and meet your cost requirements.

| Product Name | Category | Sub-Category | |||

|---|---|---|---|---|---|

| Product Name | Variety | Description | Application | Category | Sub-Category |

| CraneGlas® | 232 | CraneGlas® 232 is a nonwoven fiberglass paper constructed from fine diameter electrical grade fibers of uniform length with a PVA binder. The paper is capable of operating at high temperatures, is flame retardant and is available in a range of thickness. CraneGlas® is used in a variety of applications including: chemical trace lines, thermal insulating gaskets, copperclad laminates for printed wiring boards, battery separators and photovoltaic panels. | Fiberglass separator materials for lithium thionyl chloride cells. CraneGlas® 232 can be supplied slit to your required width in a wide variety of put ups. | Inside Cells | Battery Seperator |

| Jelly Roll Wrap | Custom desinged dielectric barrier between the jelly roll and the can. Polyimide, PET and polypropylene with chemistry compatible adhesives | Contact us with any questions about technical specifications, availability or samples. | Inside Cells | Dielectric barrier | |

| Diecut Top & Bottom Cell Insulator | Custom punched fiberglass, PTFE, Polypropyelene or PET insulators. Supplied with or without adhesive. | Contact us with any questions about technical specifications, availability or samples. | Inside Cells | Dielectric barrier | |

| Go-Therm Thermal Runaway Barrier | 150 | Go-Therm 150 is a glass one side silicone laminate, designed to be used as an interior lining of the battery case. It offers superior performance to protect the pack from the ejecta and flame caused by thermal runaway. | Go-Therm Battery Pack Thermal Runaway Barrier can be used to line the interior of a battery pack or can be used as a thermal runaway barrier between prismatic cells in a module. Parts can be fabricated to size and are available with a pressure sensitive adhesive on one side. Go-Therm is designed to be a flexible option to rigid mica plate. | Battery Packs | Thermal Runaway Protection |

| Go-Therm Thermal Runaway Barrier | 315 | Go-Therm 315 is a fiberglass backed (both sides), 1.5mm thick laminate, designed to be used as an interior lining of the battery case. It offers superior performance to protect the pack from the ejecta and flame caused by thermal runaway. | Go-Therm Battery Pack Thermal Runaway Barrier can be used to line the interior of a battery pack or can be used as a thermal runaway barrier between prismatic cells in a module, or as a module-to-module barrier. Parts can be fabricated to size and are available with a pressure sensitive adhesive on one side. Go-Therm is designed to be a flexible option to rigid mica plate. | Battery Packs | Thermal Runaway Protection |

| PET Layflat Tubes | 740HS | 740 heat shrink sleeves are extremely thin wall, heat shrinkable tubing that provide dielectric protection and physical toughness. This tubing is composed of a one side anti-static treated modified polyester film, formed into tubing. 740 heat shrink sleeves are clear in color but can be printed or colored. 740 heat shrink sleeves shrink quickly, (10seconds@100°C)and uniformly around cylindrical shapes. | Electrolock 740 linear sleeves are available in a variety of diameters and lengths. Packaging can be designed to suit machine and process requirements. | Outside Cells | Lineal Seam Tubing |

| PET LayFlat Tubes | 800FRC | 800FRC heat shrink sleeves are extremely thin wall, lay flat, heat shrinkable tubing/sleeving that provide dielectric protection and physicaltoughness. This tubingis composed of a one side anti-static treated modified PVC film, formed into tubing. 800FRC heat shrink sleeves are clear in color but can be printed or colored. 800FRC heat shrink sleeves shrink quickly, (10 seconds @ 100°C) and uniformlyaround variousshapes. | Electrolock 800FRC linear sleeves are available in a variety of diameters, widths, and lengths. Sleeves can be designed to suit machine and process requirements. | Outside Cells | Lineal Seam Tubing |

| Heat Shrink Spiral Wound Tubes | Polyester | Heat Shrink Polyester Sleeving is used to insulate thermal cut outs, connectors, capacitors and as a protective cover against abrasive or chemically harsh environments. This sleeving is made with heat shrink polyester film that will shrink in length and diameter when subjected to oven temperatures above 300oF or by use of a heat gun or similar heating device. Heat Shrink Polyester Sleeving offers high dielectric, good tensile strength, and possess excellent chemical resistance. | Heat Shrink Polyester Sleeving can be produced to your required diameter, wall thickness, and length. Normal diameter range is 0.096” - 3.00” with wall thickness from 0.002” - 0.006”. Custom colors or striping on request. | Outside Cells | Spiral Wound Tubing |

| Continuous Heat Shrink Spiral Wound Tubes | Polyester | Heat Shrink Polyester Sleeving is used to insulate thermal cut outs, connectors, capacitors and as a protective cover against abrasive or chemically harsh environments. This sleeving is made with heat shrink polyester film that will shrink in length and diameter when subjected to oven temperatures above 300oF or by use of a heat gun or similar heating device. Heat Shrink Polyester Sleeving offers high dielectric, good tensile strength, and possess excellent chemical resistance. | Our stanard spiral wound tubing supplied on continuous rolls, up to 2000' long. Used for automated assembly processes | Outside Cells | Spiral Wound Tubing |

| Pyrodox | HP5 | Pyrodox HP5 mica plate is de- signed for high temperature insu- lating applications. It has excel- lent mechanical, electrical and thermal characteristics and has a flame classification of UL 94 V-0. | Standard thickness are .1mm- 1.9mm. Standard sheet sizes are 1000mm x 600mm and 1000mm x 1200mm. Both phlogopite and muscovite versions are available. | Battery Packs | Mica Laminates |

| Pyrodox | GP400, GP500 | Pyrodox GP is a special heat treated phlogopite mica cable tape with a halogen free silicone binder and non-alkaline fiberglass backing. The tape is engineered to withstand extreme electrical and thermal overloads as well as high moisture environments which permit its use in cables having extended fire survival time. | Pyrodox is used in applications which include fire survival for control and power cables, mass transit, aircraft, oil well, thermocouple, appliance wire and shipboard cables. | Battery Packs | Mica Laminates |

| Pyrodox | EMP50-PS | Pyrodox EMP50-PS is a mica tape with a woven glass backing and a flame retardant acrylic pressure sensitive adhesive. The mica provides a flame barrier and the PSA has high tack for excellent bonding | Pyrodox EMP50-PS is available in master widths up to 39 inches, as well as custom widths and punched shapes | Battery Packs | Mica Laminates |

| Polyimide Laminates | Custom desinged dielectric barrier between the jelly roll and the can. Polyimide, PET and polypropylene with chemistry compatible adhesives | Contact us with any questions about technical specifications, availability or samples. | Battery Packs | Polyimide Laminates | |

| Cell Wrappers | Custom desinged dielectric barrier between the jelly roll and the can. Polyimide, PET and polypropylene with chemistry compatible adhesives | Contact us with any questions about technical specifications, availability or samples. | Battery Packs | Cell Wrappers | |

| Pouch Cell Edge Seal Tape | E-6644 | E-6644 consists of multilayered substrate, designed to improve cut through and puncture when insulating the edge of pouch cells. Backed with an acrylic ad- hesive, the edge seal tape pro- vide a strong, long term solution to protecting the cut edge of pouch cells. | E-6644 is available in widths up to one meter wide, or may be slit or fabricated into individual parts or rolls . | Battery Packs | Edge Protectors |

| Pouch Cell Edge Seal Tape | I-0880 | I-0880 consists of multilayered substrate, designed to improve cut through and puncture when insulating the edge of pouch cells. Backed with an acrylic ad- hesive, the edge seal tape pro- vide a strong, long term solution to protecting the cut edge of pouch cells. | I-0880 is available in widths up to one meter wide, or may be slit or fabricated into individual parts or rolls . | Battery Packs | Edge Protectors |

| Pyrel-Therm | EIG 1000 | Pyrel-Therm EIG 1000 is a thin high temperature thermal insulation material designed to meet extreme heat environments. EIG 1000 exhibits excellent thermal resistance, extremely low shrinkage, low thermal conductivity at high temperatures and excellent compression resistance. | Pyrel-Therm EIG 1000 is available in master widths up to 1016mm as well as custom widths and punched shapes. | Battery Packs | Thermal runaway protection |

| Pyrel-Therm | ES 1100 | Pyrel-Therm ES 1100 is a thin high temperature thermal insulation material designed to meet extreme heat environments. ES 1100 exhibits excellent thermal resistance, extremely low shrinkage, low thermal conductivity at high temperatures and excellent mechanical properties | Pyrel-Therm ES 1100 is available in master widths up to 1220mm as well as custom widths and punched shapes. | Battery Packs | Thermal runaway protection |

| Pyrel-Therm | RMC Mica Heat Shield | Pyrel-Therm RMC Mica Heat Shield is designed to meet the demands of extreme heat environments. It exhibits very low heat transfer and is an effective dielectric and gas barrier | Pyrel-Therm RMC Mica Heat Shield is available in master rolls up to 1 meter wide or in custom slit or punched parts | Battery Packs | Thermal runaway protection |

| Pyrel-Therm | TS 800C | Pyrel-Therm TS 800C is a thin, semi flexible sheet used in applications where high temperature and low thermal conductivity are required. It provides superior resistance to high heat and flames. TS 800C is an excellent heat shield in electronics and military applications. | Pyrel-Therm TS-800C is available in 450mm x 450mm sheets and punched parts. | Battery Packs | Thermal runaway protection |

| Pyrodox | GP 500 MICA CABLE TAPE | Pyrodox GP 500 is a special heat treated phlogopite mica cable tape with a silicone binder and fiberglass backing. The tape is engineered to withstand extreme electrical and thermal overloads as well as high moisture environments which permit its use in cables having extended fire survival time. Pyrodox GP500is usedin applications which include fire survival for control and power cables, mass transit, aircraft, oil well, thermocouple, appliancewireandshipboard cables . | The tape is provided in slit pads or trav- erse packs in lengths that can vary at the customers request. | Battery Packs | Thermal runaway protection |

| Pyrodox | HP5 Mica Plate | Pyrodox HP5 mica plate is de- signed for high temperature insu- lating applications. It has excel- lent mechanical, electrical and thermal characteristics and has a flame classification of UL 94 V-0. | Standard thickness are .1mm- 1.9mm. Standard sheet sizes are 1000mm x 600mm and 1000mm x 1200mm. Both phlogopite and muscovite versions are available. | Battery Packs | Thermal runaway protection |

| The Original Battery Mat | Standard Thickness | The Battery Mat is a tough nonwoven felt constructed from the same polymer that is used to house lead acid batteries. The Battery Mat is capable of protect- ing your vehicle from the venting of sulfuric acid in lead acid batter- ies by absorbing and neutralizing the aid before it has a chance to corrodemetalsurfaces. The Battery Mat comes in two colors and two thicknesses to custom fit your vehicles protection needs. The Battery Mat can be used in many applications including: Automotive, Tractors, Solar Energy storage, Aircraft, Marine, Fork Lifts, and many utility and Military applications. If acid is ruining your equipment, let The Battery Mat help protect it before it is too late. | The tape is provided slit to your desired width on 3” ID cores or fabricated to your size and shape requirements. | Battery Packs | Battery Mat |

| The Original Battery Mat | Heavy Duty | The Battery Mat is a tough nonwoven felt constructed from the same polymer that is used to house lead acid batteries. The Battery Mat is capable of protect- ing your vehicle from the venting of sulfuric acid in lead acid batteries by absorbing and neutralizing the aid before it has a chance to corrodemetalsurfaces. The Bat- tery Mat comes in two colors and two thicknesses to custom fit your vehicles protection needs. The Battery Mat can be used in many applications including: Au- tomotive, Tractors, Solar Energy storage, Aircraft, Marine, Fork Lifts, and many utility and Military applications. If acid is ruining your equipment, let The Battery Mat help protect it before it is too late. | The tape is provided slit to your desired width on 3” ID cores or fabricated to your size and shape requirements. | Battery Packs | Battery Mat |

Every battery pack is different. Each pack is designed specifically for its intended application. Therefore, each battery pack has different requirements for insulation placement and performance. This is where Electrolock can help. Finding the right materials for dielectric protection and thermal runaway and supplying the materials so that they fit in the limited insulation space in the pack is our specialty. We try to understand all the specific requirements of your battery application before choosing a material for testing. Dielectric strength, flame resistance, thermal protection all play a role in choosing the best material. Limited space requirements also determine the materials of choice. Electrolock engineers try to understand all of these requirements and then submit the best material options for testing.

We have a vast library of material options and are not limited to any specific material choice. Once materials are approved by the customer, we can then provide the finished parts for use in the production of the packs.