It’s no secret that heat shrink tubing is a critical element in production for many industries, from component manufacturing for automotive and aerospace to sporting goods. But PET (Polyethylene Terephthalate, or Polyester) layflat tubing, while also being heat shrinkable, maximizes the impact of this versatile element for battery production.

Heat shrink tubing is often used as a release layer on tooling — such as mandrels, and inflatable bladders — to allow products and parts to freely be removed from tooling after curing. Heat shrink tubing is applied to the tooling before the composite matrix layup or prepreg is added to ensure the free release and is seen as an ideal alternative to more traditional (and manually intensive) options of hand-taping or adhesive release tapes.

However, beyond use as a release layer, heat shrink tubing can also be implemented as a wear-resistant or insulating cover for different products and applications. Different materials should be used depending on the application and PET layflat tubing matches perfectly with the needs presented in battery insulation.

Electrolock has decades of experience in providing the support you need to solve your battery insulation problems — both inside and outside the cell. Let’s examine two such solutions featuring PET layflat tubing.

We Provide Solutions: In this video, learn how Electrolock collaborates with customers to find the customized solutions they need to move the needle for their business.

PET Layflat Tubing for Outside the Cell Protection

Outside the cell protection, like battery insulation sleeving, is critical for the continued safe and ideal operation of batteries. Such insulation ensures each cell contained in a module is protected from other cells in that enclosed environment.

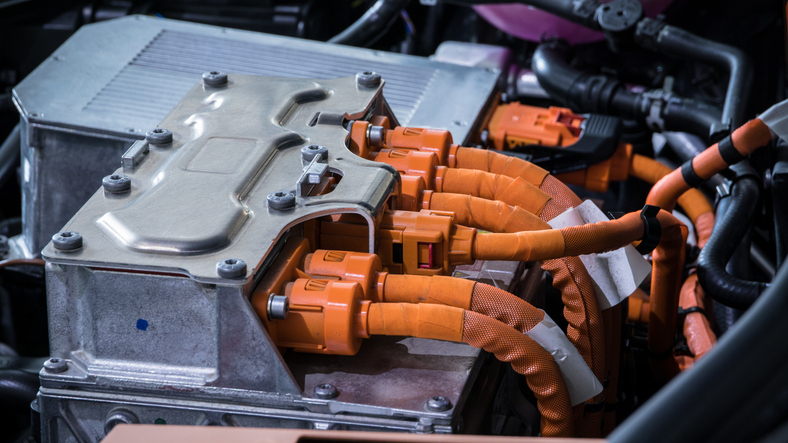

This is a crucial element for many industries, but outside the cell protection and insulation are especially relevant for Electric Vehicles (EVs). EVs need vast amounts of energy to operate — stored in high-voltage batteries that require perfect electrical insulation to function correctly. EV batteries feature three distinct units contained within one another — individual cells, groups of cells contained within a module, and the battery pack. This means dielectric protection outside of each cell is of the utmost importance to safety and efficiency.

Strong Combination of Material and Fabrication

PET layflat tubing is a heat-shrink solution that fits perfectly with this specific industry and other battery sleeving applications. Part of the reason for this is material.

Polyester and PET films and tubing offer high dielectric strength, ensuring a proper protective barrier between the power-containing cell and its environment. PET tubing also can be made with an extremely thin wall, has a higher shrink percentage than similar materials (such as FEP), and can be heat activated to begin shrinking at around 60°C (140°F).

Where shrink tape is designed to wrap around a composite part before the curing process, layflat tubing is designed to shrink around tooling (as mentioned earlier) or post-cured parts (like batteries) to provide protection. This leads to several advantages over a tape solution:

Faster sleeving — With PET layflat tubing, sleeving tools is a much simpler process and sleeving individual parts can be automated — with the removal of hand application and removal processes.

Prevents FOD — Foreign object debris is common with hand-taping and can negatively affect performance. With PET layflat tubing, sleeving is consistent without the risk of contaminants finding their way onto the tool or part surface.

Reduces Mark-Off — Ensuring a clean, consistent surface finish is critical, but with taped-on release liners or other adhesive products, the results can be anything but. Because PET layflat tubing only has a small seam down its length (lineal sealing), the impact on the surface finish is drastically reduced or eliminated altogether.

Two Electrolock Examples of PET Layflat Tubing

Electrolock provides battery insulation solutions that are available in a variety of diameters and lengths. Our solutions can be designed to suit machine and process requirements.

PET Layflat Tubing 740 HS

This lineal seal tubing comes as heat shrink sleeves with an extremely thin wall that provides both dielectric protection and physical toughness. 740 HS tubing is composed of a one-side, anti-static treated modified polyester (PET) film that is clear in color but can be printed on or colored. Formed into tubing, 740 heat shrink sleeves shrink quickly — roughly in 10 seconds at 100°C — and uniformly around cylindrical shapes.

PET Layflat Tubing 800 FRC

Another lineal seal tubing solution, 800 FRC heat shrink sleeves also have an extremely thin wall that offers dielectric protection and physical toughness. This tubing differs from the 740 HS version in that it features a one-side, anti-static treated modified PVC film. But, just like the 740 HS, the 800 FRC is clear but can be printed or colored and shrinks quickly — again in 10 seconds at 100°C — and uniformly around multiple shapes.

Need Tape, not Tubing? Learn more about Electrolock’s polyester heat shrink tape options that provide compression and a clean release.

Learn More from our Experts in High Voltage Insulation Testing

Electrolock has been engineering solutions for the high-voltage electrical, battery, and thermal insulation industries since 1957. Our focus remains focused on creating unique and tailored solutions to service the most demanding requests. We have distributor relationships and engineering experience to find the right application solution for you.