Electrolock has been supplying some of the highest quality mica insulation tapes to some of the largest OEMs for decades. Key to these relationships is our extensive knowledge base — from our engineering team through to the president of our company — and access as a certified distributor for essential distributors. For instance, the Isovolta Group is established as a leading manufacturer of electrical insulation materials, technical laminates, and composite materials. Isovolta mica tapes are well known for their quality and Electrolock is proud to offer them as part of our electrical insulation solutions.

Electrolock strives for excellence in every design and solution we offer and works directly with customers to ensure all our products meet their specific application requirements. With more than 60 years of serving high-voltage motor and generator manufacturers, and wire and cable manufacturers, Electrolock is proud to play a part in making the electricity millions use every day a consistent and reliable resource.

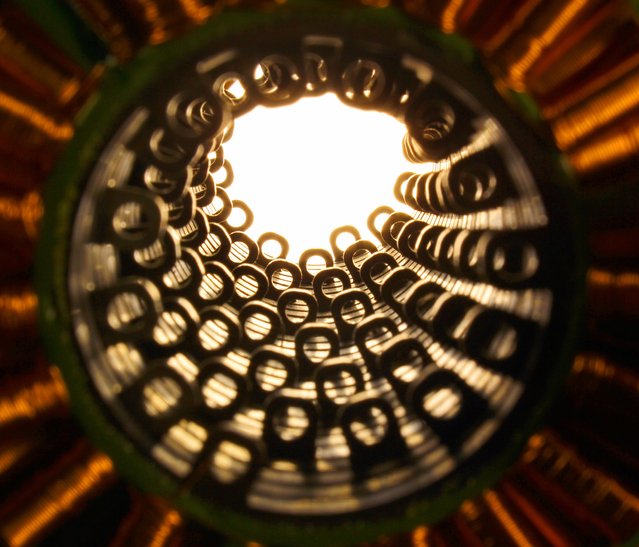

Isovolta mica tapes play a huge role in this mission and serve as a vital part of many insulation solutions. Rotating electrical machines must permanently withstand maximum stress. A perfectly coordinated insulation system forms the foundation for meeting these high standards and achieving the desired performance of generators, motors, and drives. With decades of experience in processing mica and various resins, Isovolta offers the highest quality mica tapes for generators of all types and sizes.

Electrolock applies its approach of finding bespoke solutions to specific applications that our customers face. Working from a pair of North American locations, Electrolock will consider every facet of your individual application and then tap into our array of engineering expertise and distributor partnerships to find the ideal answer. Today, we’ll examine the types of mica used for coil insulation and take a quick look at Isovolta mica tape examples of each.

Looking for compacting tape instead? Electrolock also has shrink and release tapes to facilitate the processing of high-voltage coils and composites. Learn more here.

Types of Mica Used in Medium and High Voltage Coils

Because of its higher electrical purity, nearly all medium and high voltage coils use muscovite mica. Muscovite mica is processed in two ways: a calcined process and an uncalcined process. Both methods produce high voltage mica tapes that exhibit high breakdown voltages, good voltage endurance, and low dissipation factors. While both tapes have sufficient electrical properties, in general, calcined muscovite exhibits slightly higher breakdown, and uncalcined muscovite mica typically has greater voltage endurance.

Calcined Muscovite

In the calcined process, chunks of flake muscovite mica are passed through a high-temperature rotary kiln (sometimes called a rotary calciner) and the tumbling heat breaks some intermolecular bonds. This exfoliates the flake and allows for various mixing equipment to produce very small mica flakes. These tiny, calcined muscovite flakes have a small diameter-to-thickness ratio. When made into a paper and then high voltage ground wall insulation, the calcined mica paper tapes exhibit a high voltage breakdown.

Uncalcined Muscovite

Under the uncalcined process, the chunks of flake mica undergo an ablative process using high-pressure water jets that break up the rock into small mica flakes with a large diameter-to-thickness aspect ratio. These flakes are then segregated by size to assure a consistent mica paper with the proper flake diameter-to-thickness aspect ratio. Mica tapes made with uncalcined mica paper exhibit longer voltage endurance because of the longer tracking path around the larger aspect ratio flakes. There is also more mica per given thickness when compared to calcined papers.

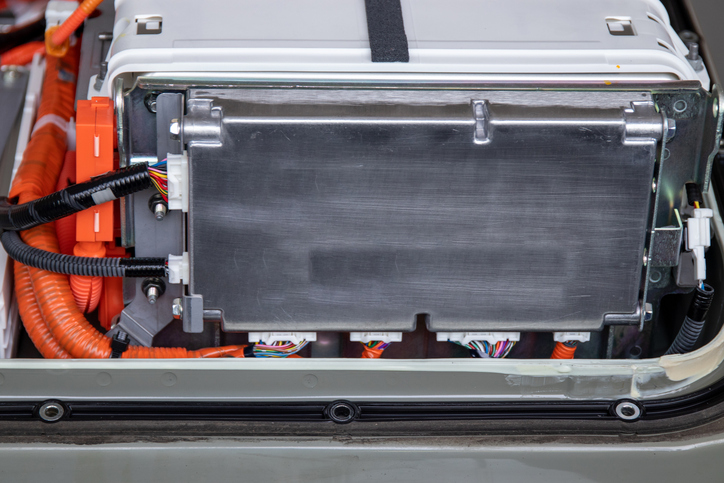

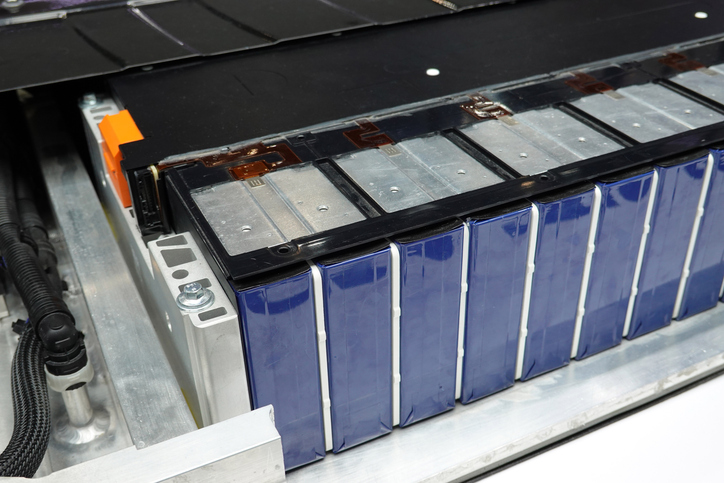

Explore Our Battery Solutions: Electrolock covers every aspect of battery insulation, from dielectric barriers to thermal runaway protection. See more here.

Popular Uses for Different Isovolta Mica Tapes

It should be stressed that you can make acceptable high voltage insulators with either kind of mica tape, but each has its own particular strengths and preferred intended uses. Calcined mica is generally preferred in medium voltage vacuum pressure impregnation coils and is often made with higher binder contents. In medium-voltage coils impregnation is easier because of the lower insulation builds. The calcined mica tapes with higher binder content are more durable, and easier to tape, and voltage stress is typically much lower making voltage endurance requirements easier to satisfy. Calcined muscovite mica is also preferred in most resin-rich tapes for both medium and high voltage coils because the smaller aspect flakes are less susceptible to blocking in self-wound resin-rich tapes.

- Isovolta Mica Tape example — Calmicaglas® 409 consists of mica paper based on calcined muscovite, a glass cloth carrier, and thermosetting epoxy-novolac. This mica tape is used for insulation of coils and bars of motors and generators up to the highest output and nominal voltage and also can be used for manufacturing molded parts like commutator caps, tubes, and cylinders.

Uncalcined mica tapes are predominantly used in the high voltage vacuum pressure impregnation process. Uncalcined mica tapes are typically made with low binder levels, with contents around 8 percent by weight. These low binder tapes are more fragile and typically applied with robots where the taping tension and taping angles are more controlled and consistent. The advantage of the low-binder, high aspect ratio mica flake tapes is easier impregnation through thicker ground walls and higher voltage endurance when voltage stress is greater. There are new resin-rich tapes on the market taking advantage of the increased mica-to-thickness ratio, however, as blocking can be an issue so it is important to take special care during manufacturing and taping.

- Isovolta Mica Tape example — Poroband® 410 consists of highly porous mica paper based on uncalcined muscovite, reinforced on one side with glass cloth, and a small amount of Bisphenol-A epoxy-resin. Poroband® 410 does not contain any accelerator or hardener and is used for impregnation with accelerated resins. The low bonding content and the uncalcined mica paper are responsible for the high porosity of the tape, which enables a quick penetration of resin through a considerable number of layers. This tape is used for continuous insulation of coils and bars of low and high voltage machines as well as interlayer insulation in dry type transformers if the vacuum pressure impregnation process is used.

Both types of mica tape have been used successfully for decades in many different applications and designs. Understanding the slight benefits of each can help distinguish which might be best for your specific application. The two examples of Isovolta mica tapes above represent only a small sampling of the many kinds of mica-based tapes the manufacturer offers.

Tailored Solutions for Stator Coils and More: Electrolock offers an extensive list of solutions for applications relating to VPI stator coils and bars, and resin-rich stator coils.

Make Electrolock Your Mica Tape Partner

Electrolock has been engineering solutions for the high-voltage electrical, battery, and thermal insulation industries since 1957. Our focus has always and will continue to be focused on creating unique and tailored solutions to service the most demanding requests. From insulating motor and generator coils to wire and cable tapes, we have distributor relationships and engineering experience to find the right application solution for you.