When seeking insulation materials for extremely harsh environments, discerning engineers will often elect to go with mica tape for cables and wiring due to its fire resistance, extremely high dielectric strength, and excellent thermal stability.

First, What is Mica??

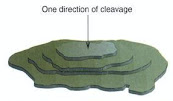

Mica is the name given to a group of minerals that naturally forms in layers with a two-dimensional structure. Because of this two-dimensional structure, mica can be split, or cleaved, into very thin sheets. Specifically, mica has near-perfect “basal cleavage”, meaning it can be easily split into one plane. This allows mica to be processed into very thin films while retaining high dielectric and thermally resistant properties.

In the electrical industry, mica usage is dominated by two types — muscovite and phlogopite. Phlogopite is amber or dark green in color, has excellent heat resistance, and outperforms during voltage endurance testing over time. Muscovite also has exceptional heat resistance and can endure higher voltages during voltage breakdown testing. We’ve detailed both calcined and uncalcined muscovite before and how each could be the better choice depending on the desired application.

Why Use Mica Tape for Cables?

The properties of mica make it an excellent choice for wire and cable insulation in applications with exposure to high temperatures and direct flame. Fire safety applications require emergency power and communication circuits to remain operational during a fire. It is critical that fire alarms in buildings and exhaust fans in tunnels continue to operate well after being exposed to direct flames and temperatures up to 1800 F. Additional benefits of mica insulation in wire and cable applications include its characteristics of being flexible, lightweight, chemically inert, hydrophobic, and durable.

How is Mica Applied to Wire and Cable?

First mica is broken down to create mica paper — a paper-like material made of miniature mica flakes held together by natural cohesive force between adjacent flakes. Mica paper is very fragile and requires further processing to add strength and durability. Mica paper is combined with various reinforcing substrates and bonding resin to create mica tape. The thermal, electrical, and mechanical requirements of the application weigh heavily on the bonding agent and substrates selected.

Mica tapes are applied to wire and cable at high speed continuously by means of a linear or spiral wrapping machine.

Multiple Custom Mica Tape Solutions from Electrolock

Since 1957, Electrolock has provided premier insulation products for the high voltage electrical, battery, and thermal insulation industries. This experience and expertise are evident in the development of Electrolock’s proprietary Pyrodox® mica cable tapes.

As one of the many high voltage electrical insulation solutions Electrolock provides, Pyrodox is used in essential and demanding applications including fire survival for control and power cables, oil well, thermocouple, aircraft, mass transit, and shipboard cables. Pyrodox mica tape for cables offers the high-temperature resistance and thermal insulation that comes with the use of thin mica paper bonded with halogen-free silicone resins to the appropriate substrate for your application.

With Electrolock, you’ll gain access to engineering consultation and customization options to maximize the success of your application. Pyrodox cable tapes are available in thicknesses of less than .003” for taping ultra-fine wire gauges. These tapes can be precision-slit to widths of less than 1/8th of an inch and supplied on custom spools (traverse, step, taper, etc.) containing thousands of yards of continuous tape. Long continuous tape lengths reduce taping machine downtime resulting from pack changeovers.

You also won’t be locked into one configuration. Pyrodox can be customized using any combination of the following materials. Each combination is engineered to meet your application’s unique requirements.

- Pyrodox® Mica Types

- Phlogopite

- Calcined phlogopite

- Muscovite

- Calcined muscovite

- Synthetic

- Pyrodox® Reinforcements

- Woven fiberglass

- Inorganic yarn

- Polyethylene film

- Polyester film

- Pyrodox® Binder

- Non-alkaline, halogen-free, high-temperature silicone binder

- Pyrodox® Coating

- Inorganic coating can be applied to either side of any configuration to decrease flaking, stringing, and sticking issues during high-speed wrapping.

Wrap Up Insulation with Mica Tape for Cables

Electrolock’s focus has always been on creating bespoke products, tailored to each client’s specific needs. You won’t simply pick a product from a catalog; you’ll work with Electrolock’s team to develop a custom-designed solution.