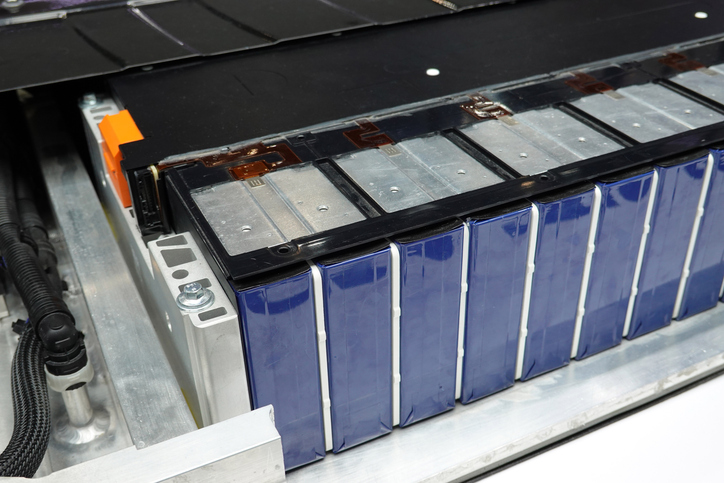

There seems to be an endless array of electric motor topologies, architectures, and configurations. Among the many design choices that engineers face is the shape of copper wire that is wound in the stator.

In a new paper published in the IEEE Transactions on Industry Applications, researchers compared using flat wire hairpin winding and stranded round wire in some of the most common motor technologies found in EVs: induction, synchronous permanent magnet, and wound field machine topologies.

Read the Charged EVs article about how Tecnomatic uses innovative designs in hairpin stator systems to reduce heat and improve torque in EV traction applications. Similarly, Electrolock has developed a custom slot liner that also helps maximize the amount of copper in the slot resulting in more horsepower.